Inspection

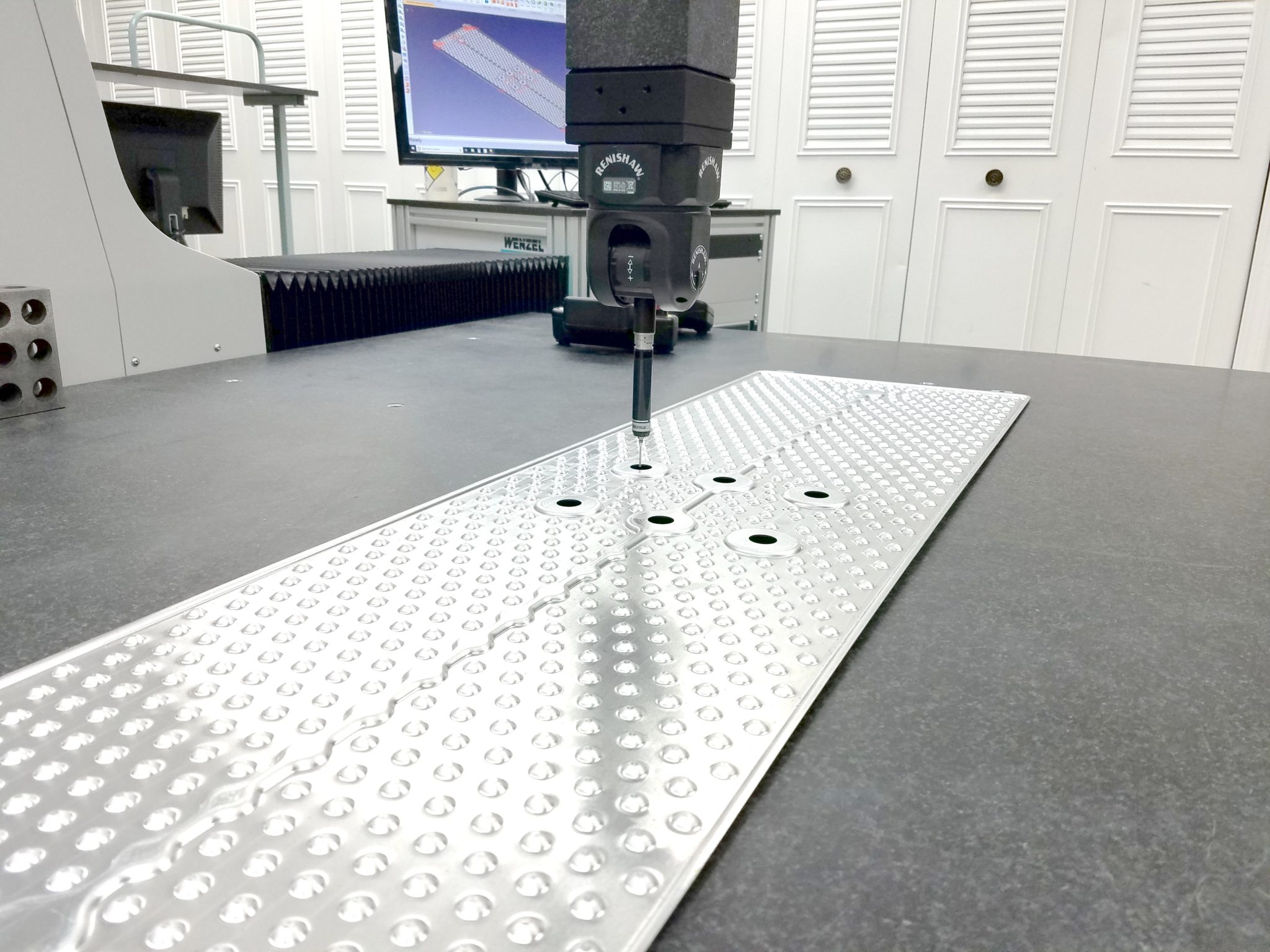

With our certification in ISO 9001, you can rely on the experts at Quasar when it comes to quality, accuracy and reliability. Our reputation of high quality is one of our most valuable assets. Quasar’s Quality Assurance Department inspects each component utilizing one of our CAD based CMMs. Dimensional reports can be supplied electronically in a number of formats with full graphical reporting capabilities. All our equipment is certified to the U.S. Bureau of Standards and meets all automotive standards as well as MIL-I-45208 and MIL-STD-45662. With our continual improvement policy, our quality assurance manual is regularly updated to ensure we are delivering high quality products on-time at a cost effective rate.

We have the ability to inspect your project to your CAD model or supplied DWG utilizing:

Software

- PC-DMIS

- Nikon CMM-Manager

- Innovmetric PolyWorks Inspector Premium

- QC-Calc Software to aide in CPK and SPC Studies

Hardware

- Wenzel XO 10.12.7 with UCC T5 Controller & Renishaw PH20 Probe

- Starrett DCC CMM; 64″ x 40″ x 24″

- Faro Edge arm with Faro Blue Light HD Laser Scanner

- 4 Manual CMMs; up to 64″ x 40″ x 18″

- Tensile Tester with 20,000 lb load cell

- Antonik AERM Hardness Tester

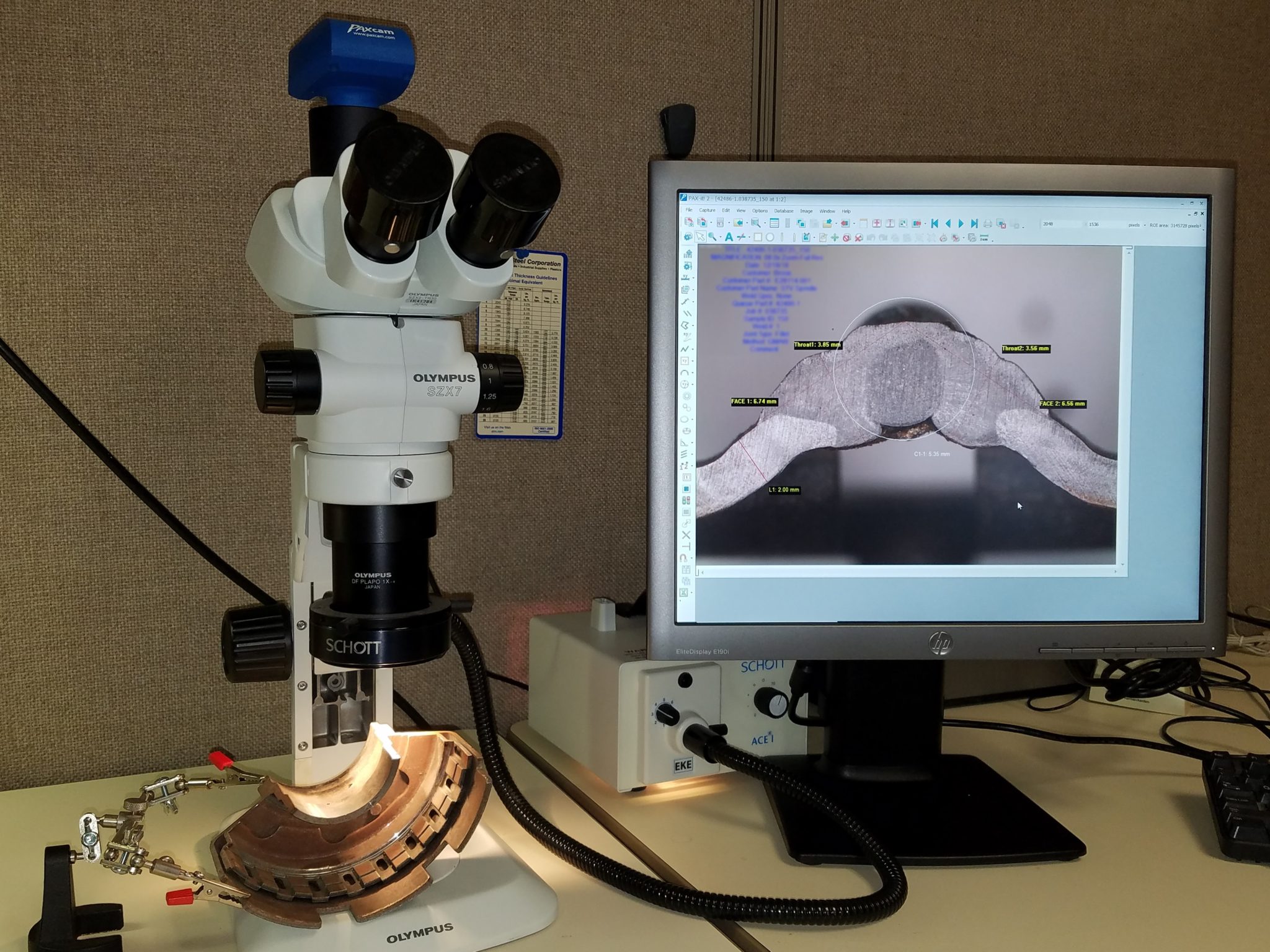

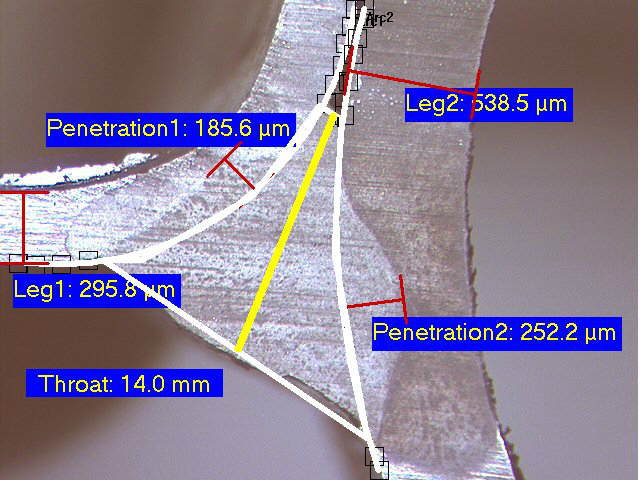

- Olympus SZX7 Stereo Microscope, up to 56x Zoom with PAXcam3 Digital Camera and PAX-it Software