Services

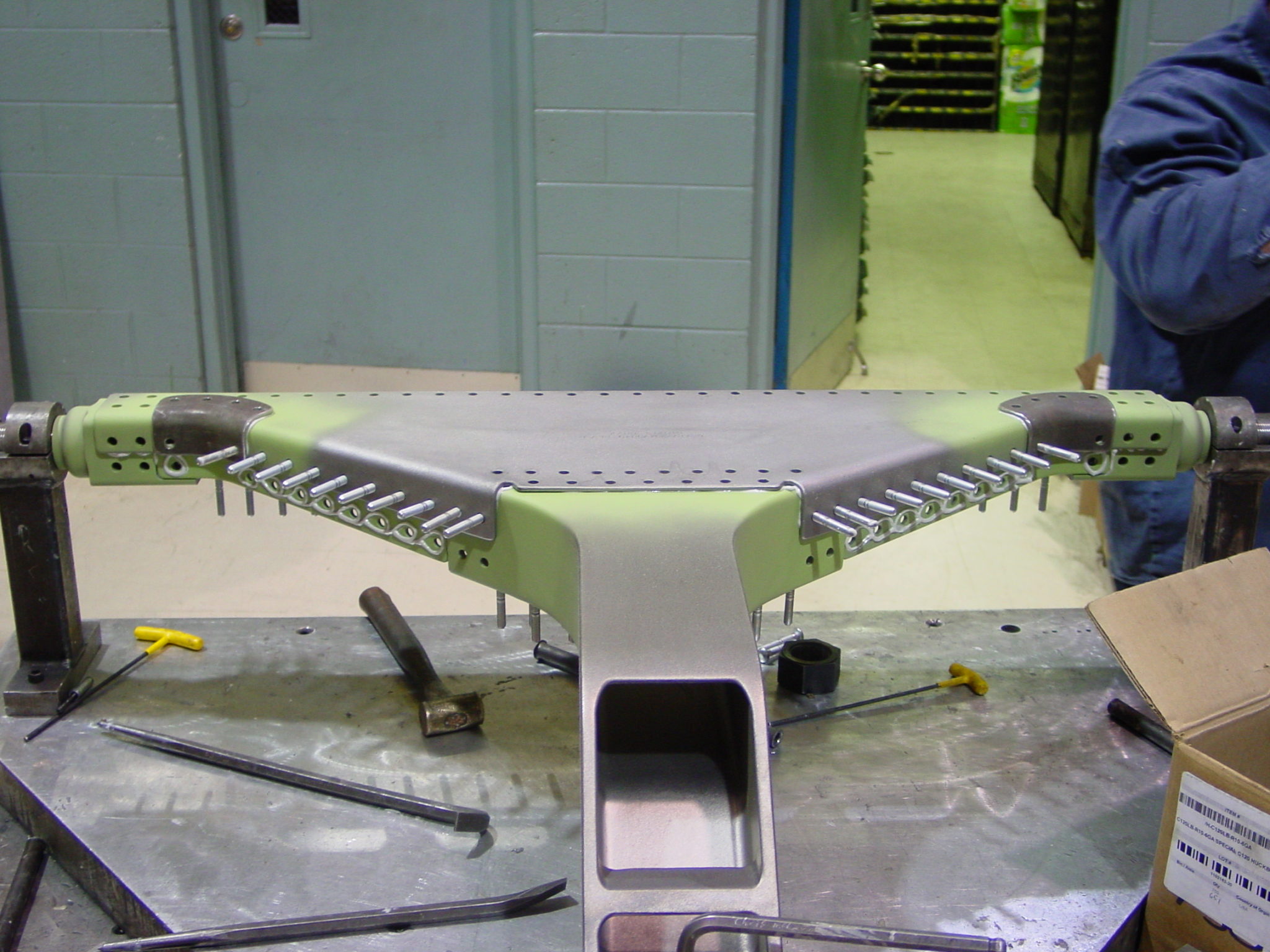

Assembly

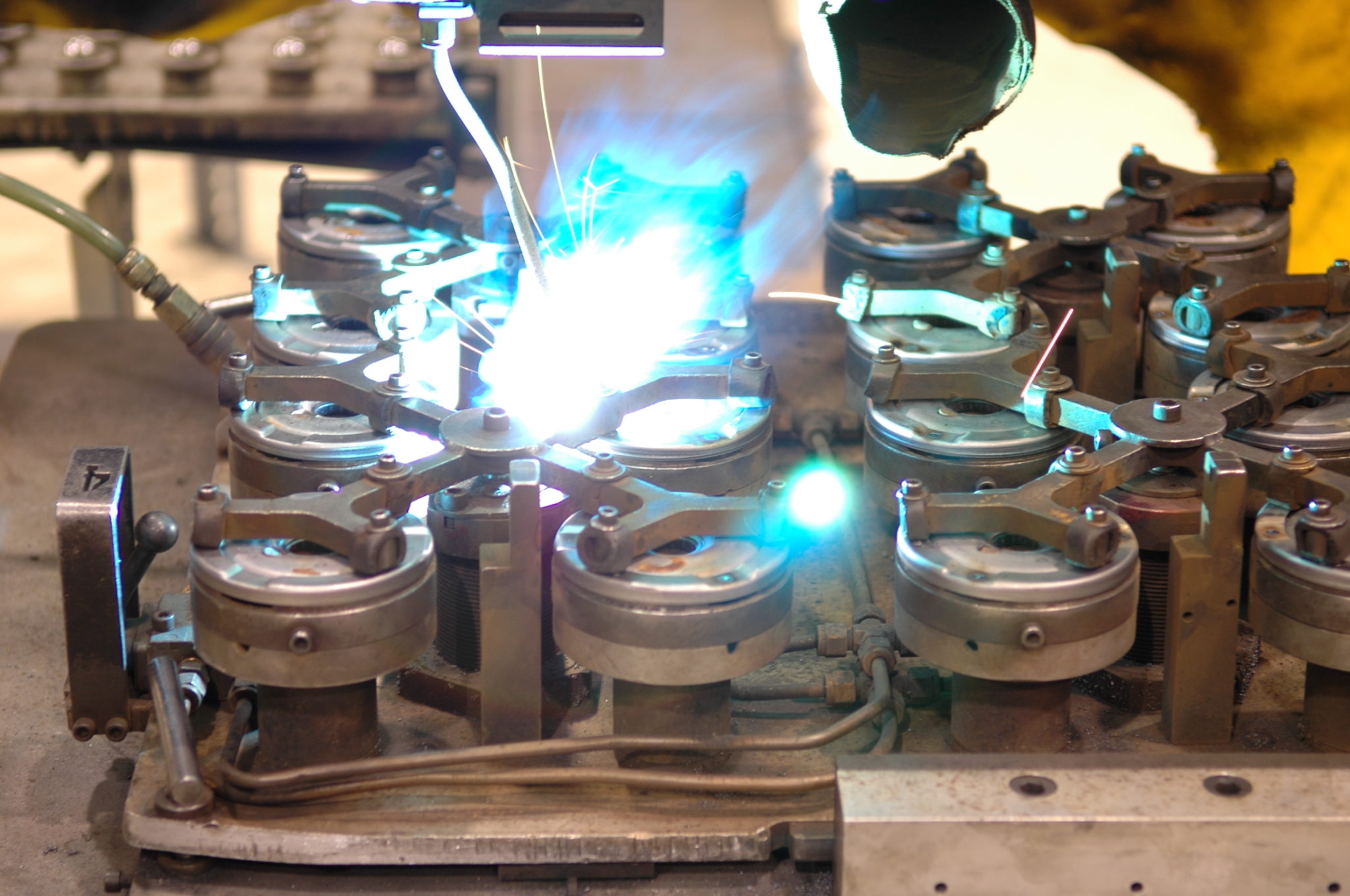

- Certified MIG and TIG welding

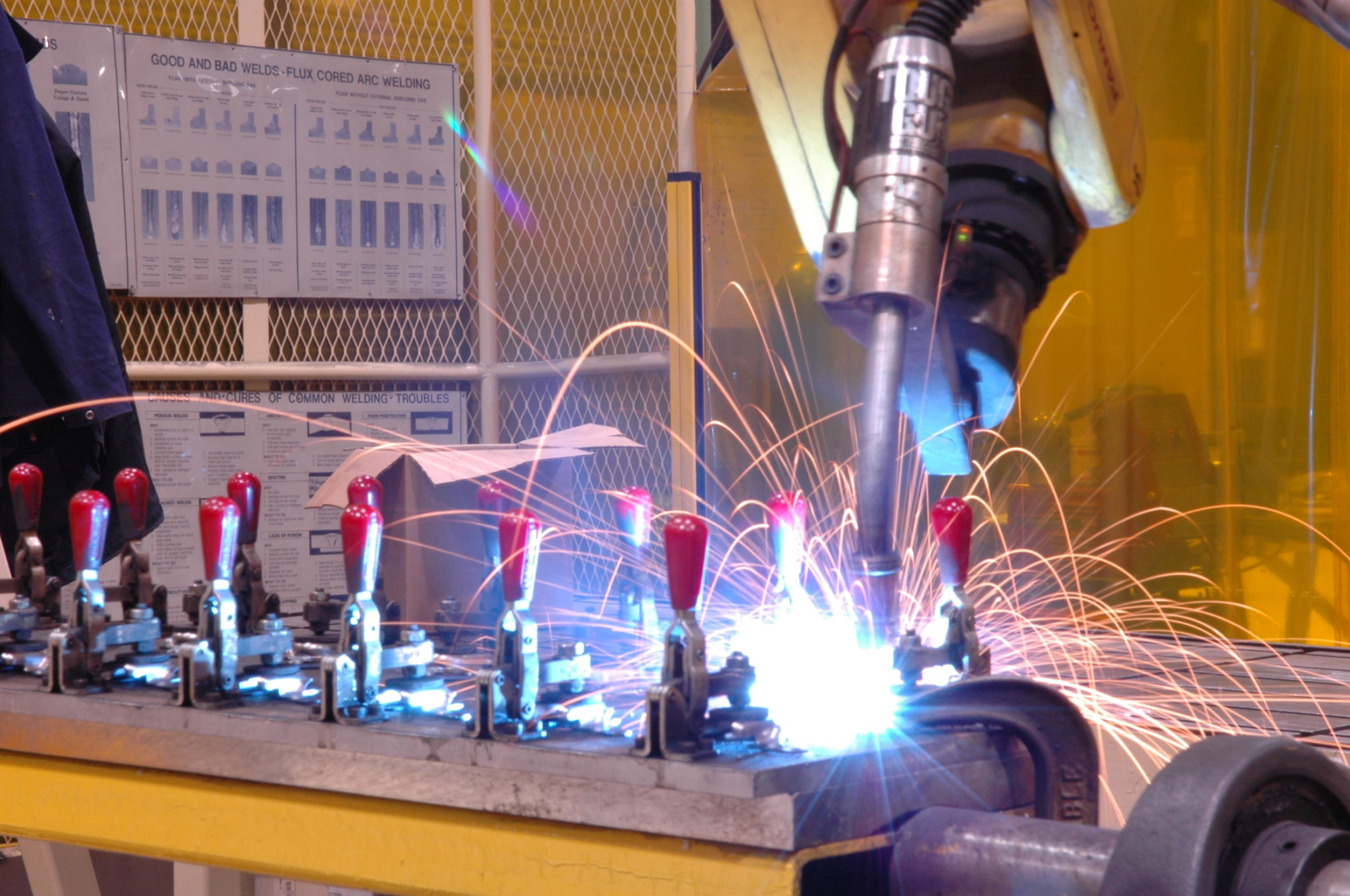

- Robotic MIG welding

- Laser welding

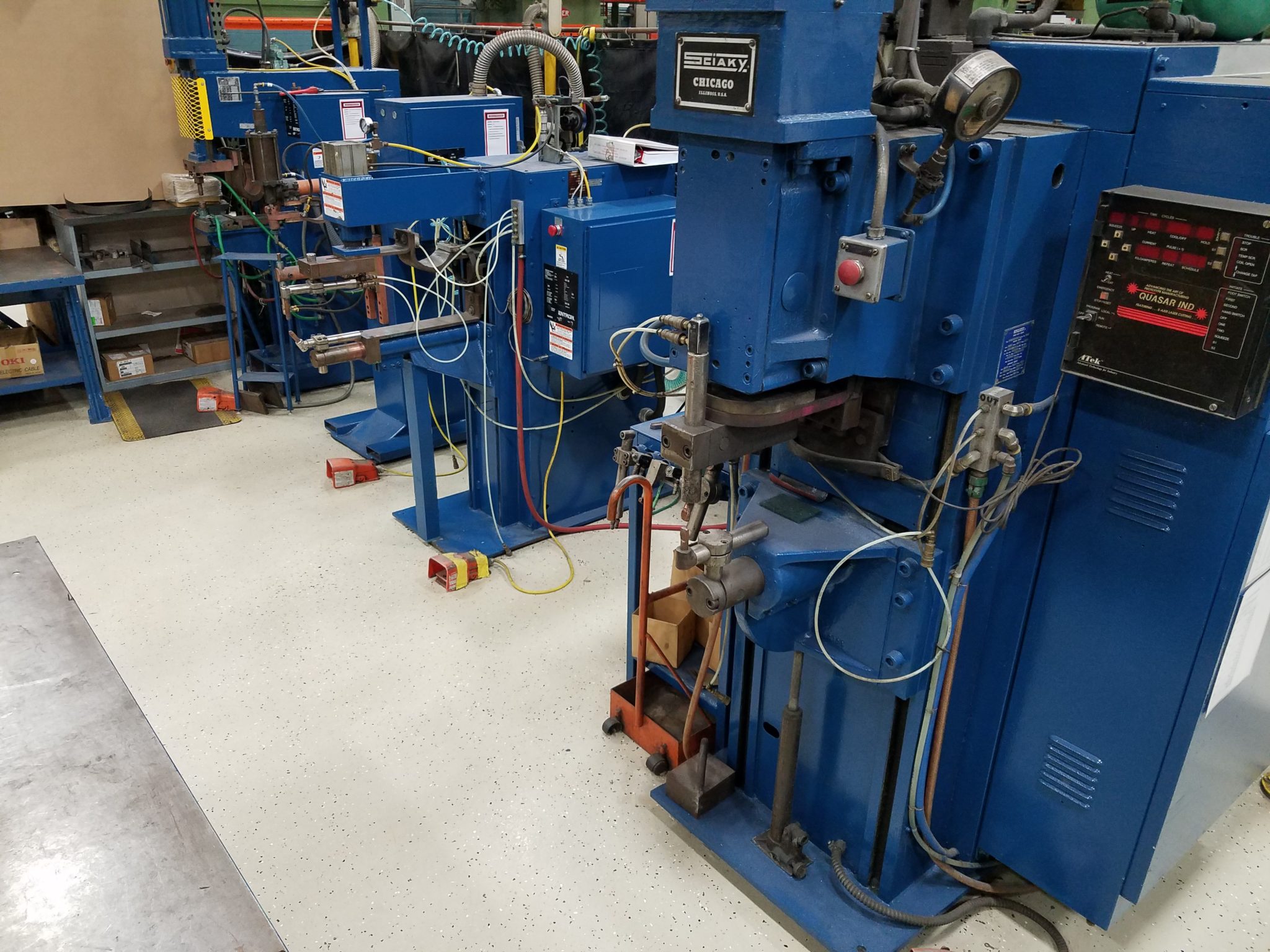

- Spot welding

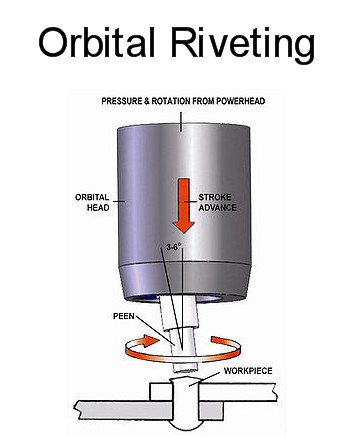

- Spin riveting

- Glue & rivet assembly

- Sheet metal clinching

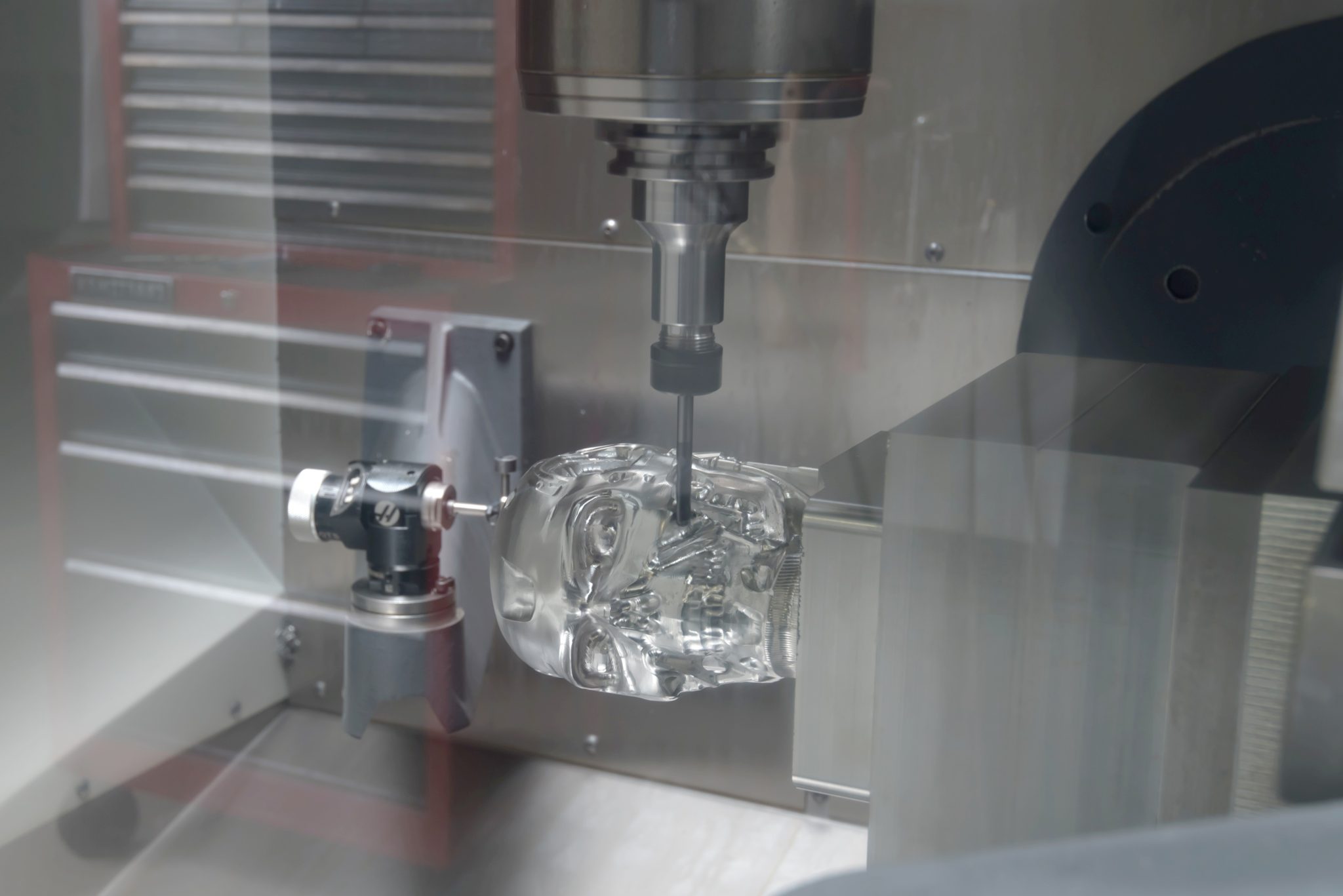

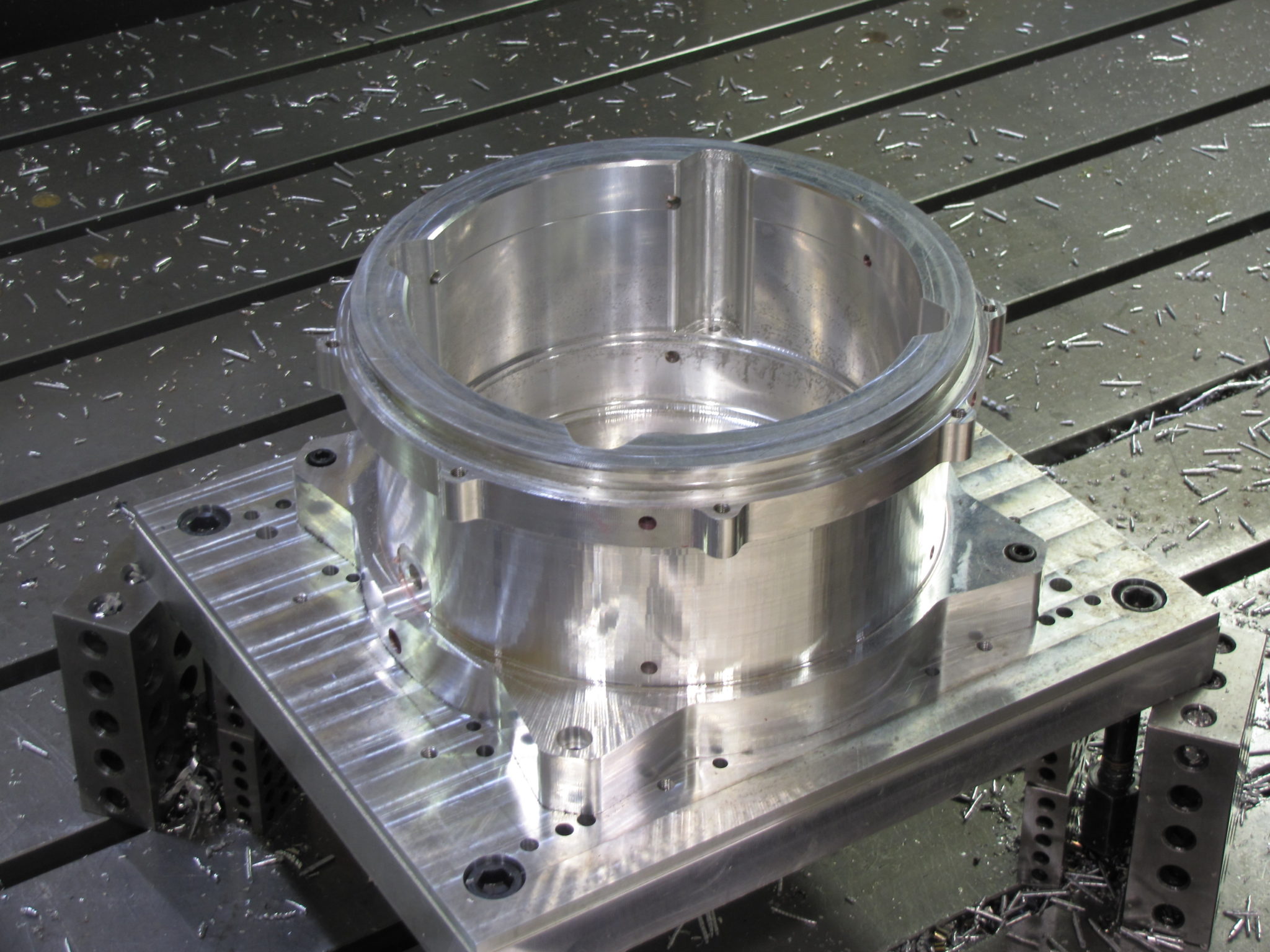

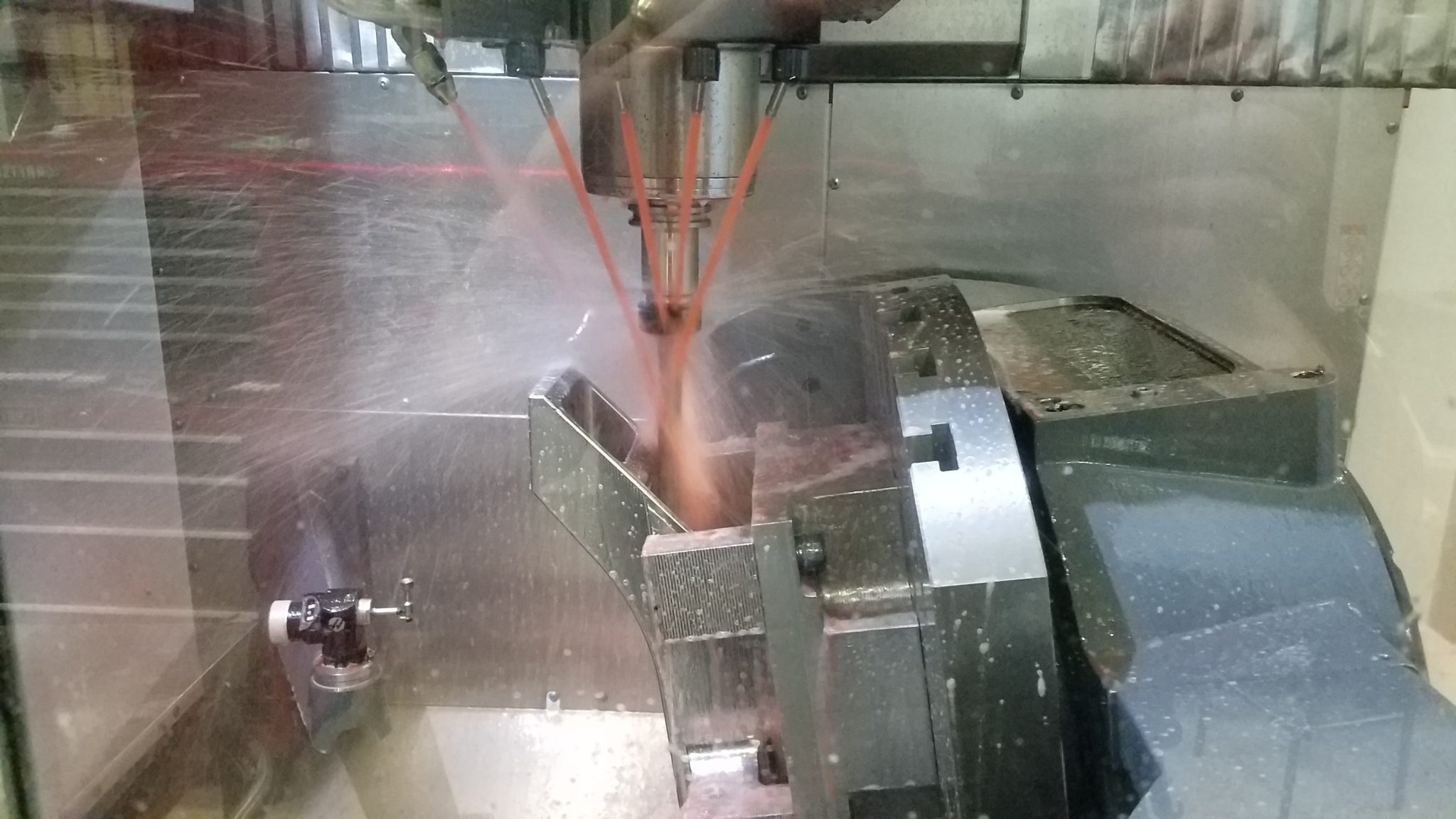

CNC Machining

- High speed machining

- 3 & 4 axis machining

- Simultaneous 5-axis machining

- High speed CNC lathe with “Live Tooling”

- Working envelopes up to 160″ x 60″ x 30″

- Manual Bridgeports and lathes

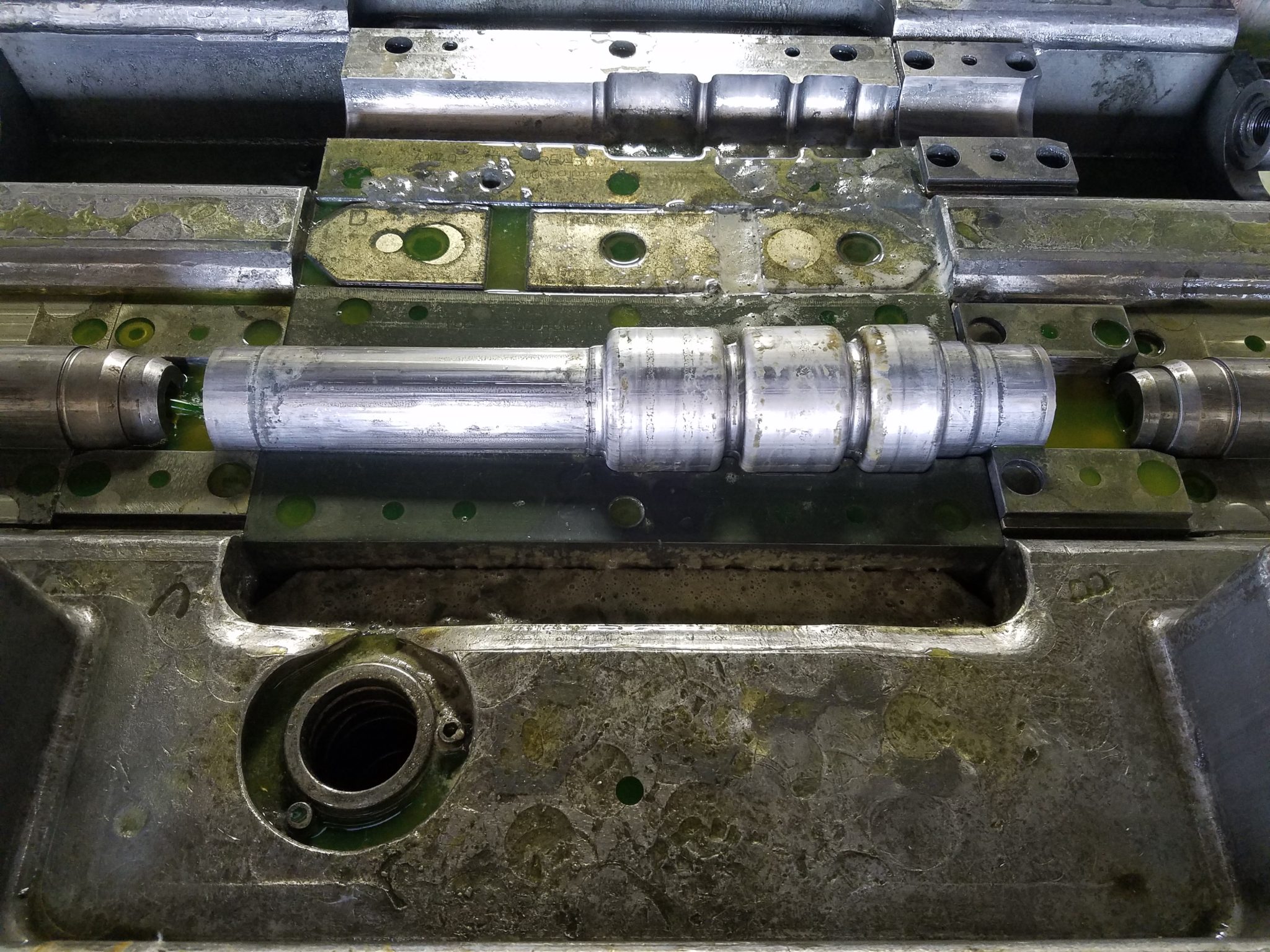

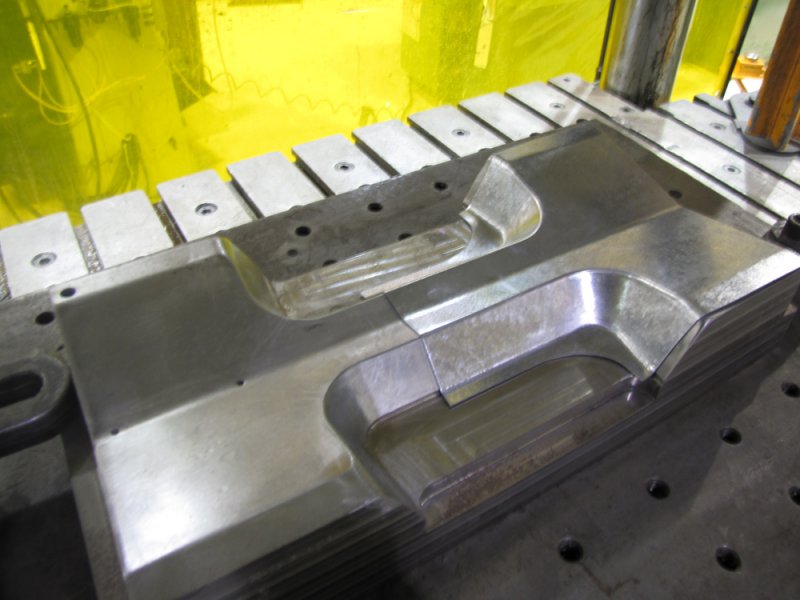

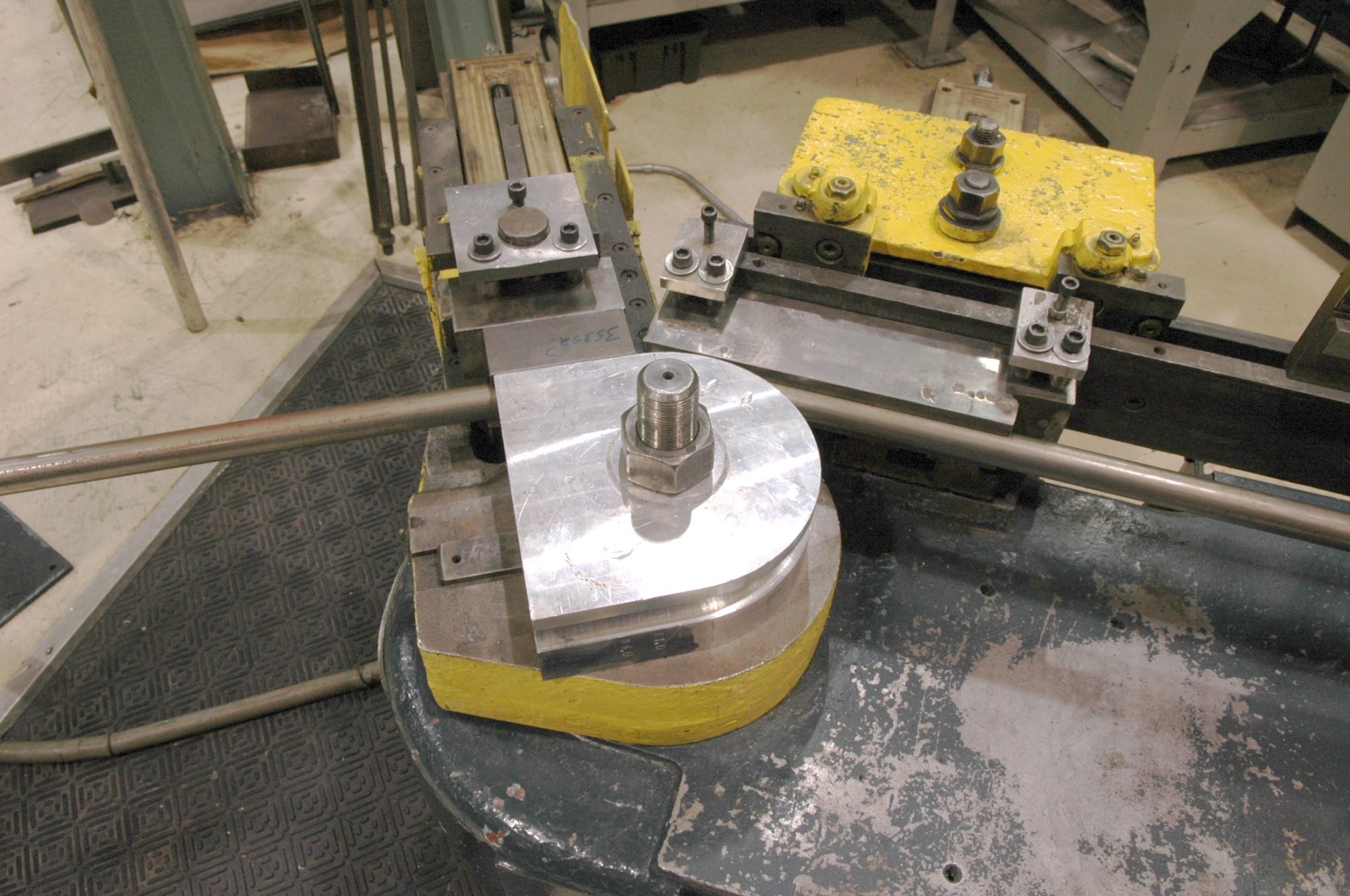

Hydroforming

- Tubular hydroforming up to 4000 bar (58,000 psi)

- 178″ x 85″ bed size

- 5500 ton clamping force

- 400 ton end feed force

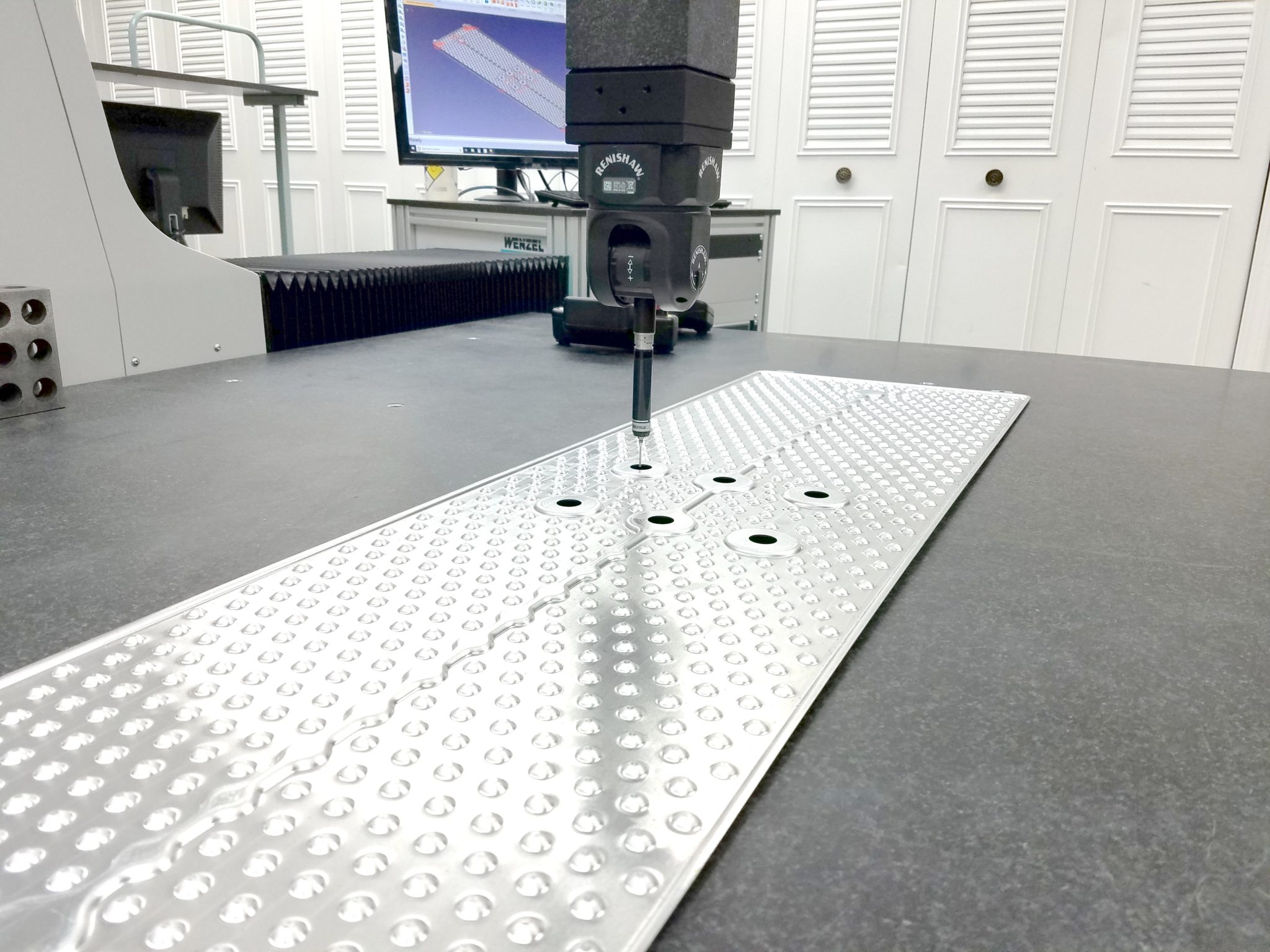

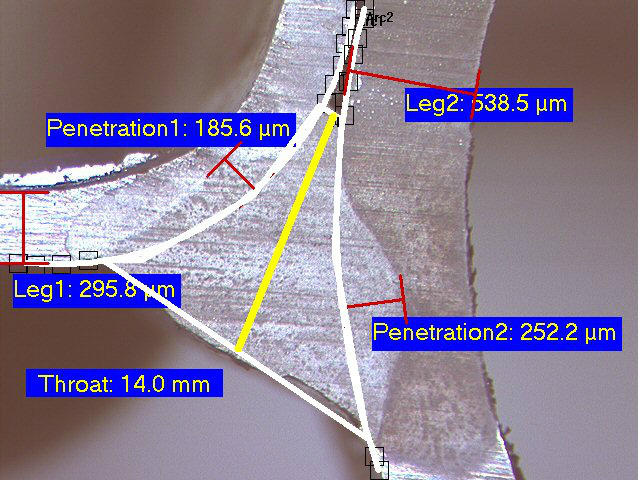

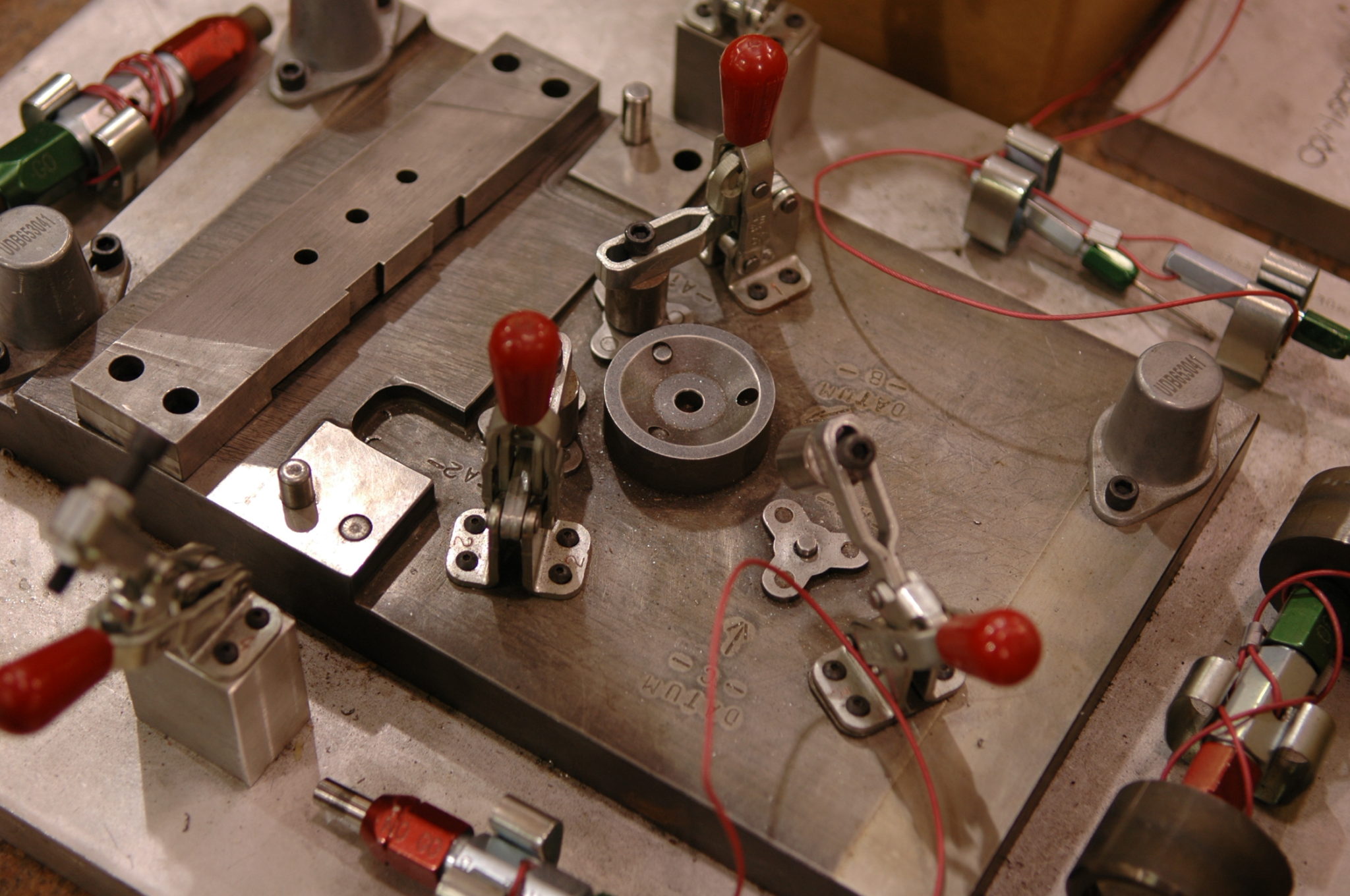

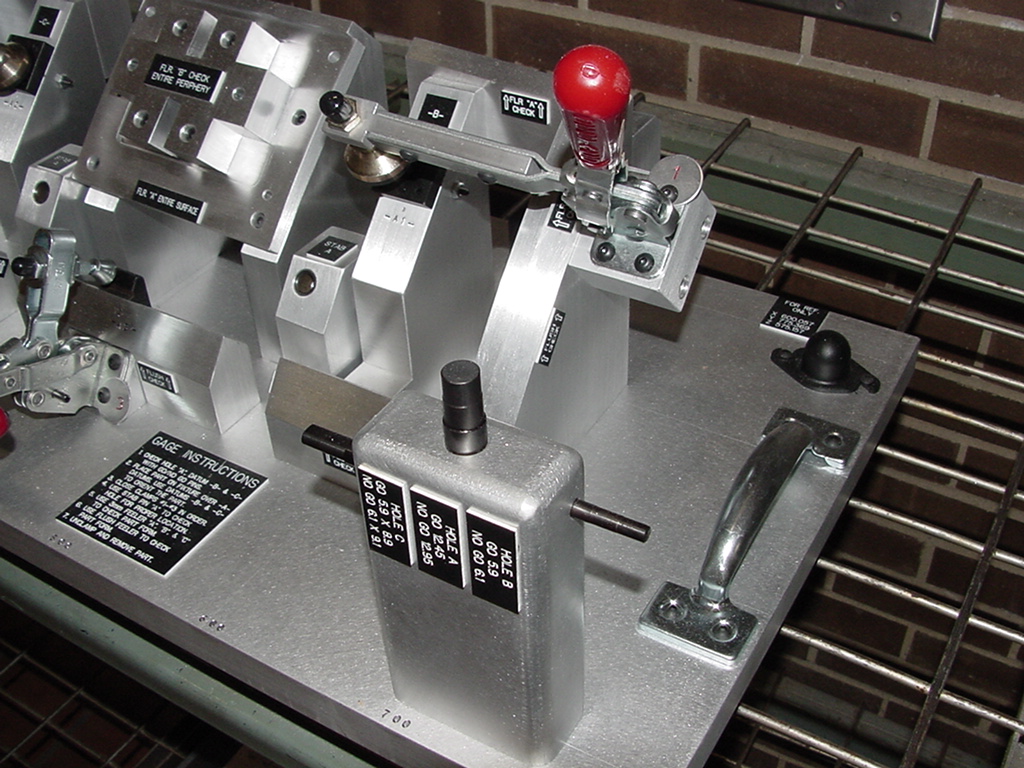

Inspection

- UCC T5 Controlled CMM & Renishaw PH20 Probe

- FARO EDGE Arm with FARO Laser Line Probe HD

- Manual CMMs up to 64″ x 40″ x 18″

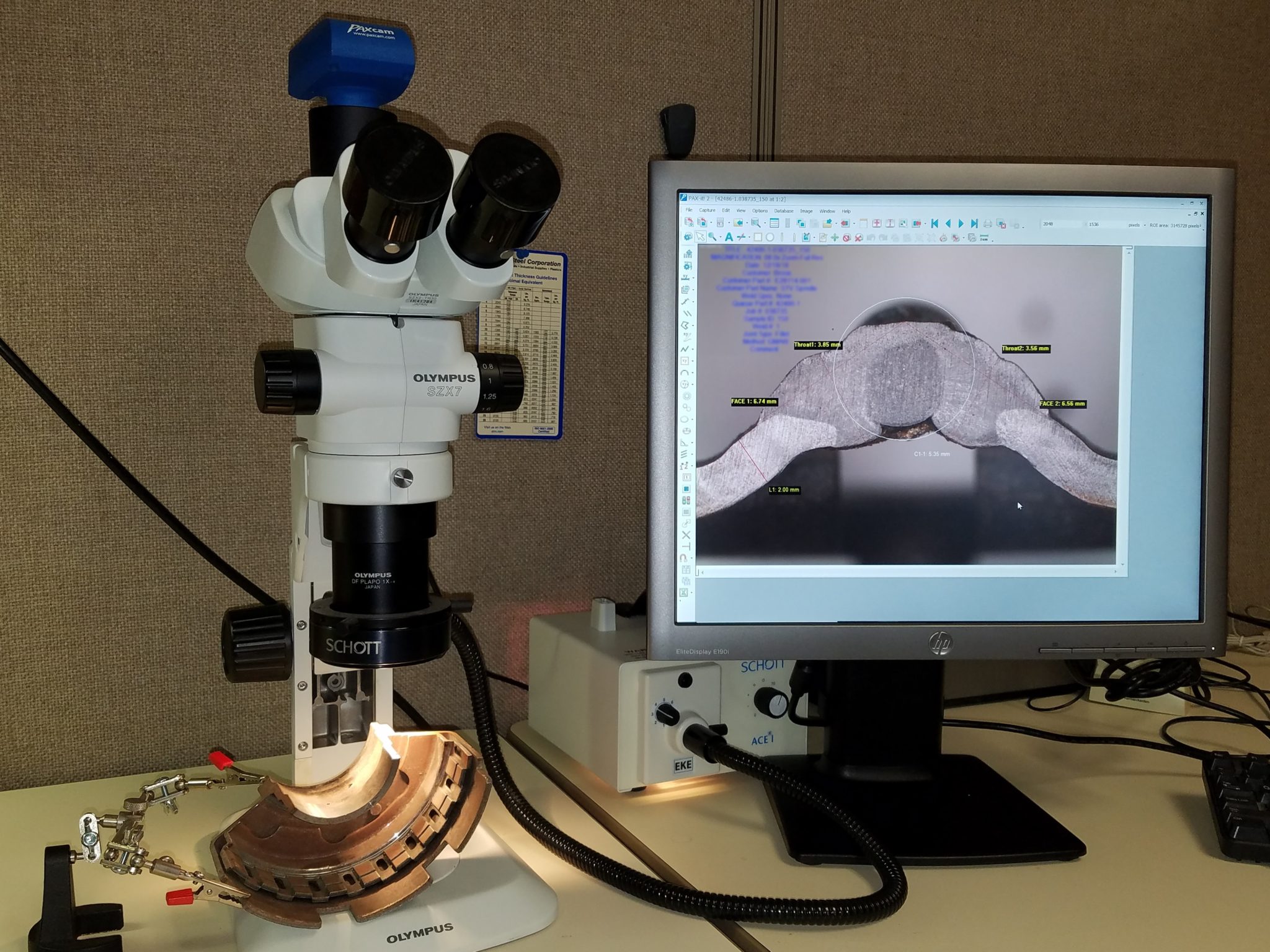

- Tensile and hardness testing

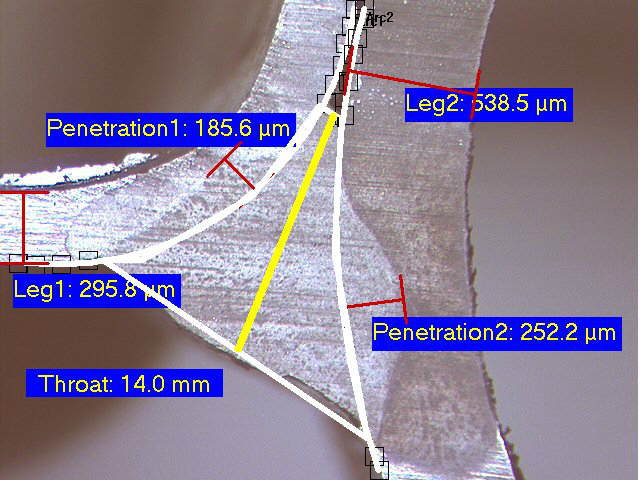

- PAXcam3 Digital Microscope

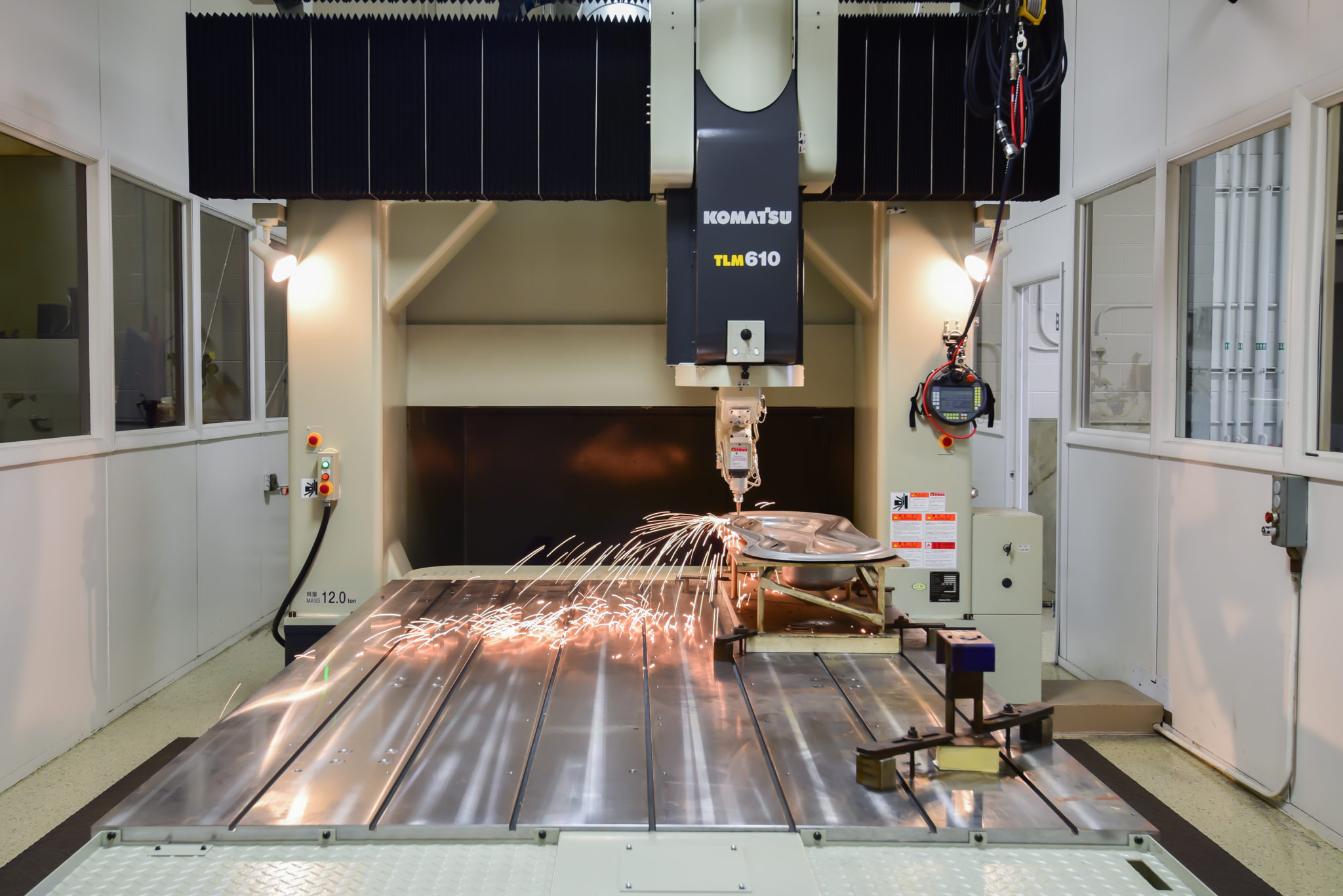

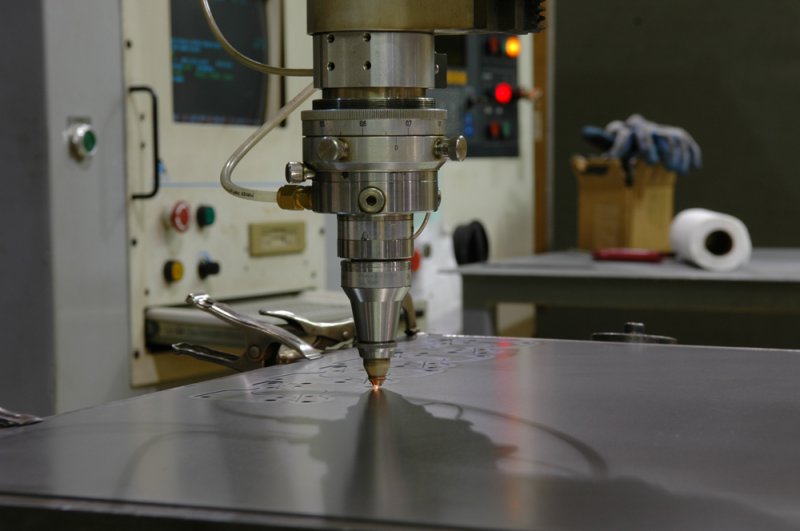

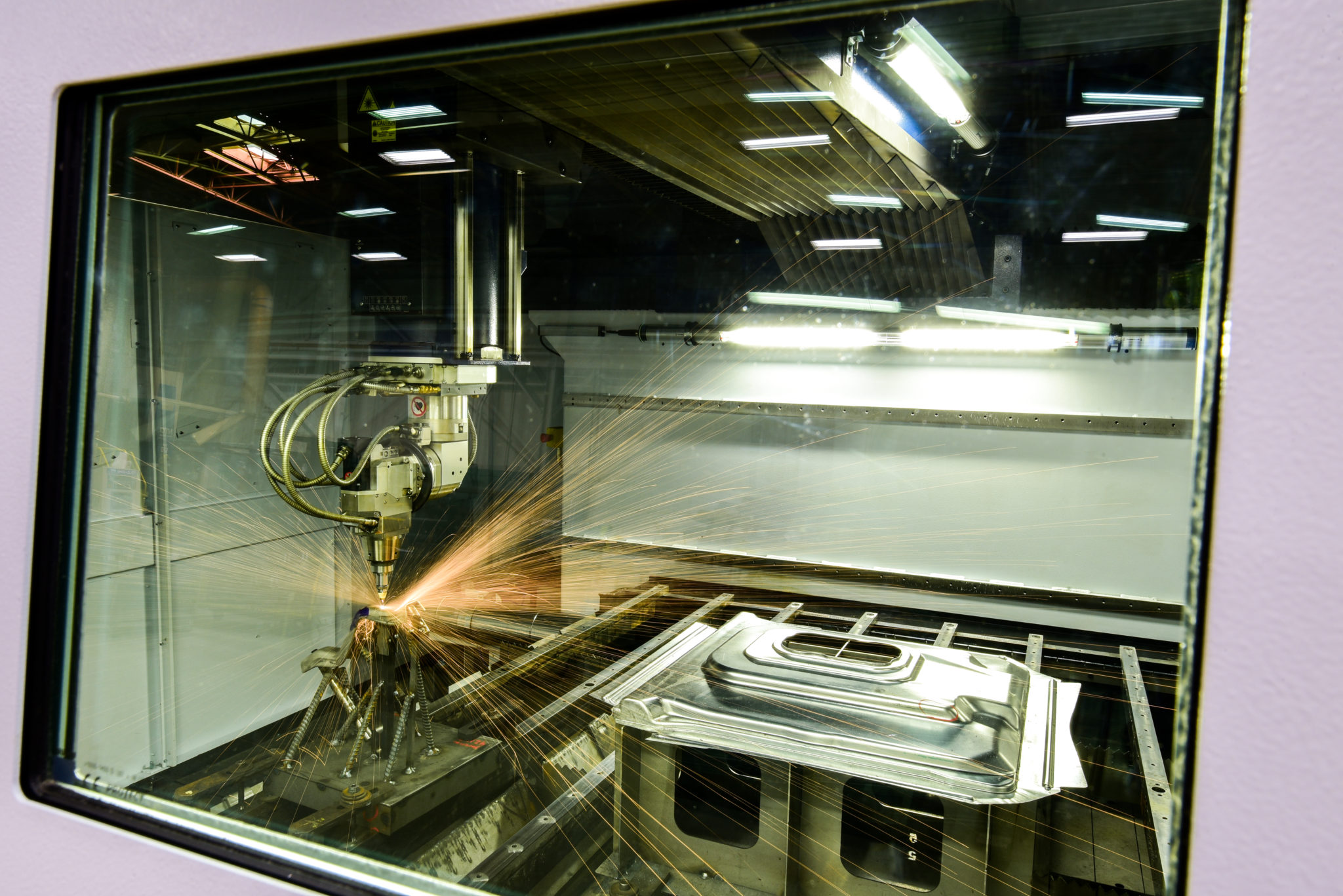

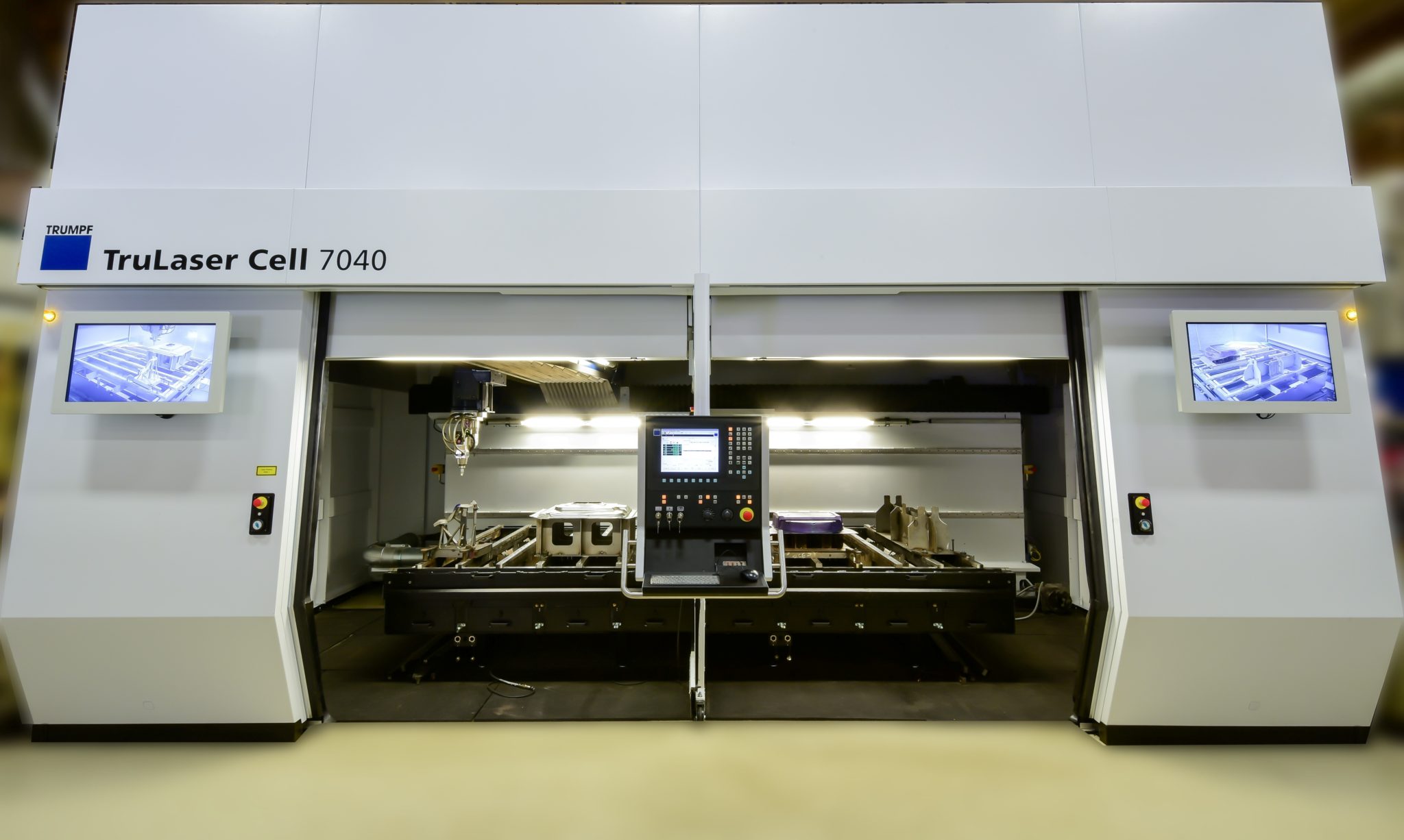

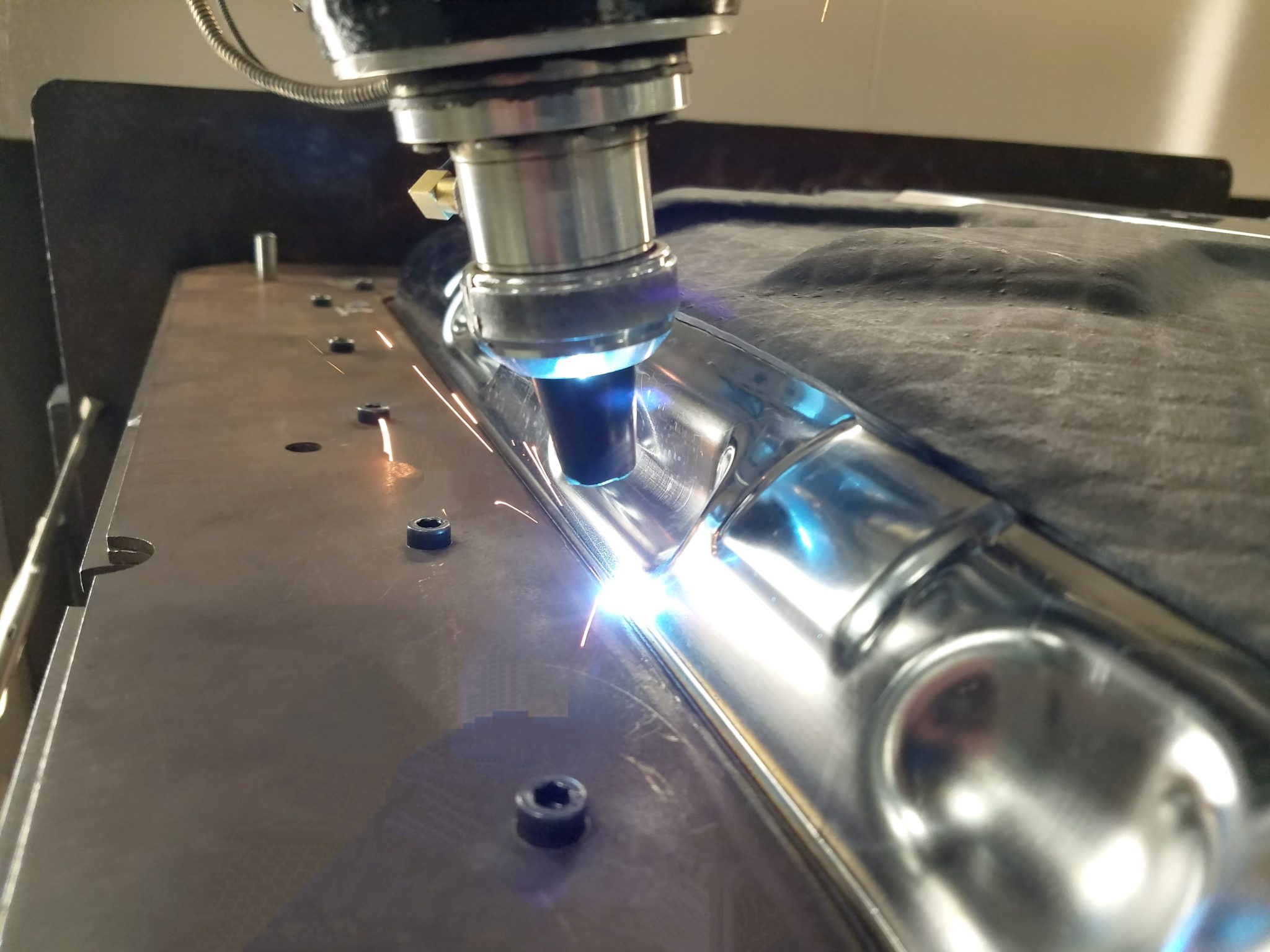

Laser Cutting

- Flat and 5 axis laser cutting

- CO2 and fiber technologies

- Various materials including aluminum, stainless, copper, and steel up to 1.0″ thick

- Up to 156″ x 78″ envelope

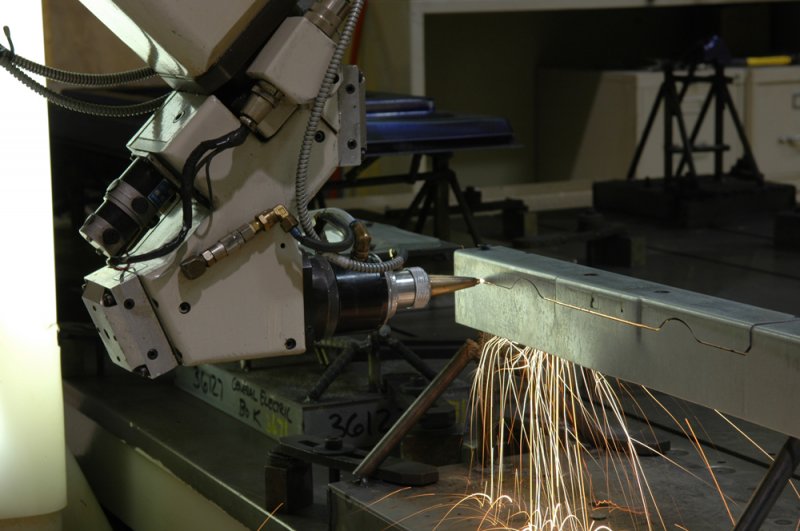

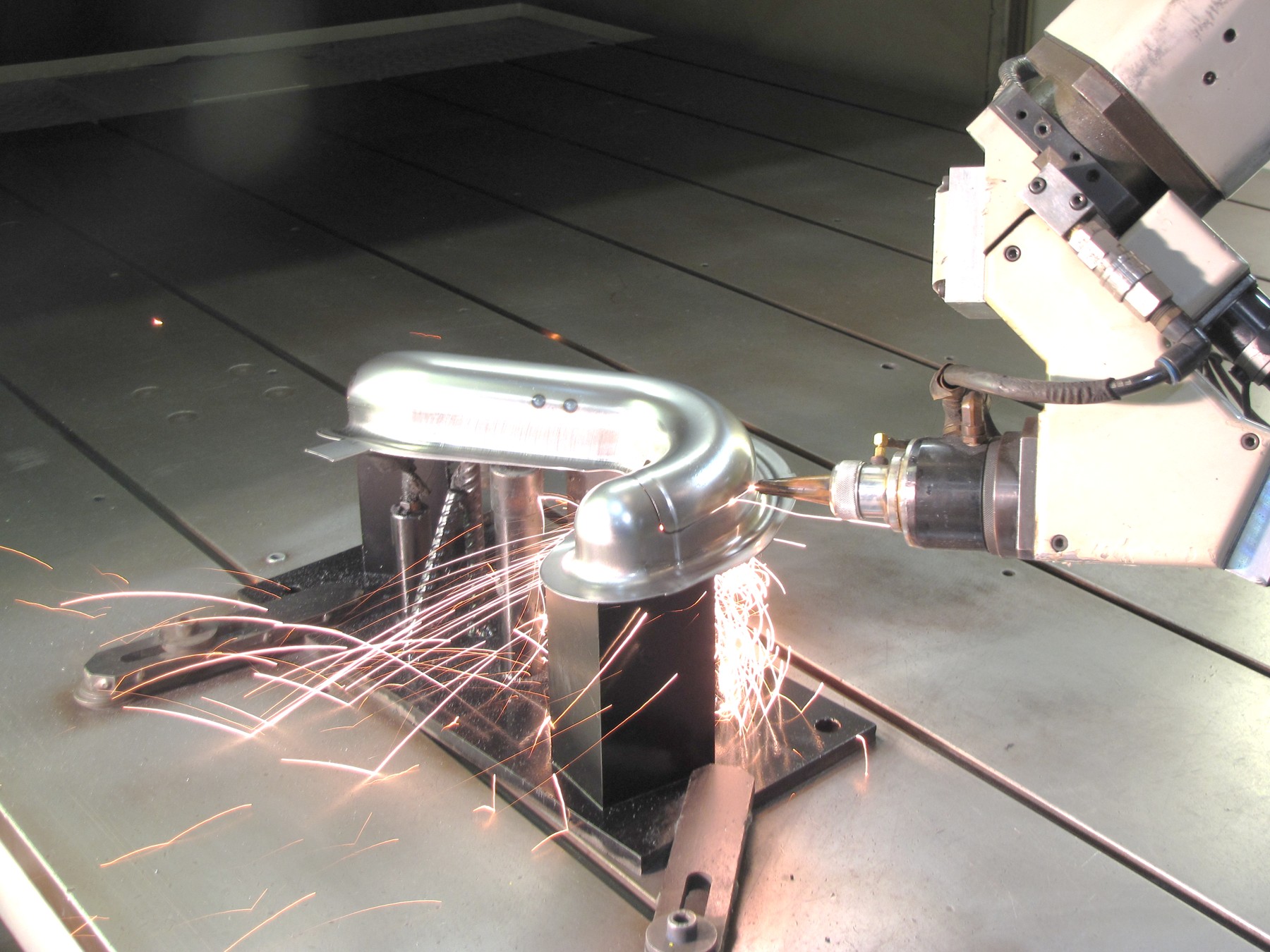

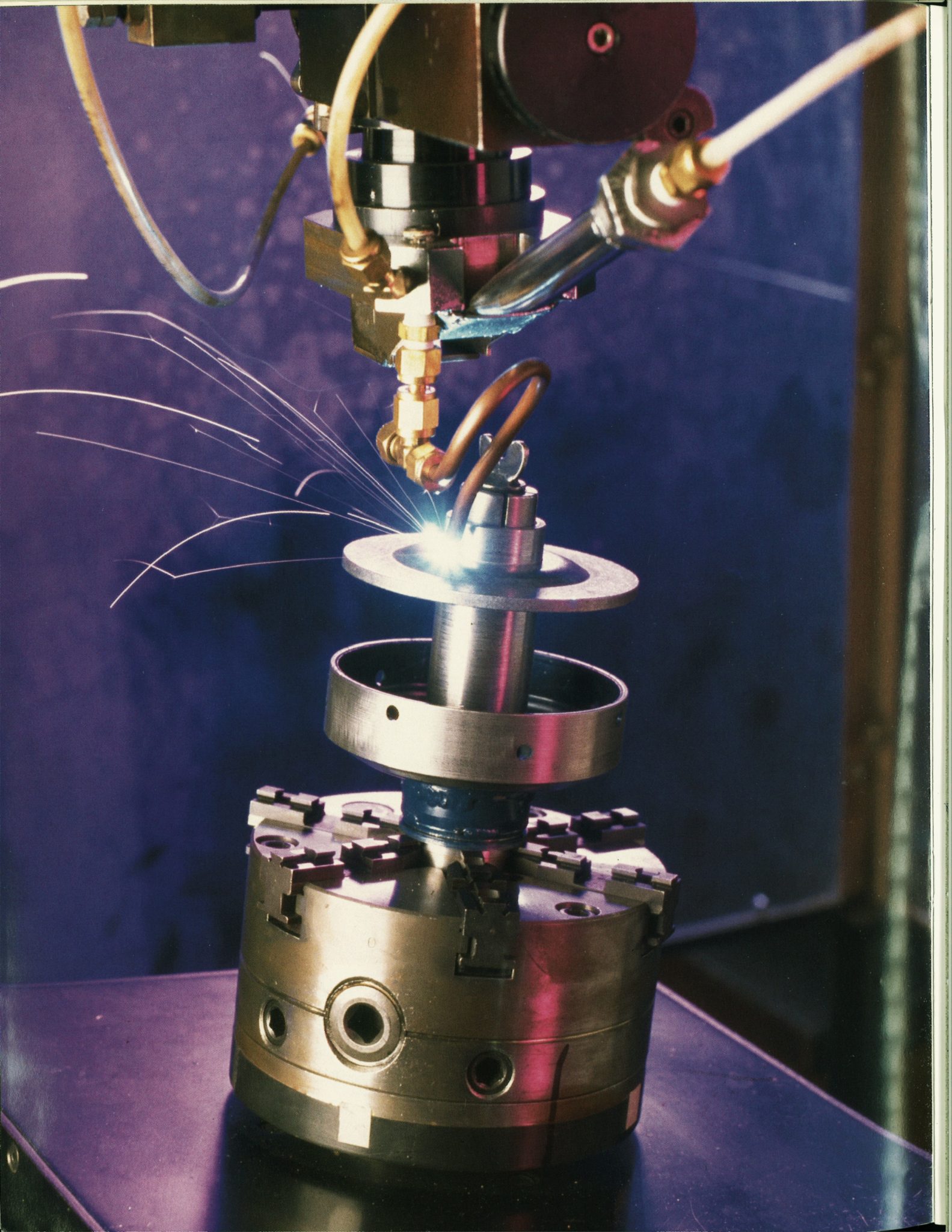

Laser Welding

- CO2 laser welding up to 8,000 watts of power

- Fiber laser welding up to 3,000 watts of power

- Weld penetration up to 8mm in depth

- Tailor welded blanks, high tolerance transmission components

- Up to 156″ x 78″ envelope

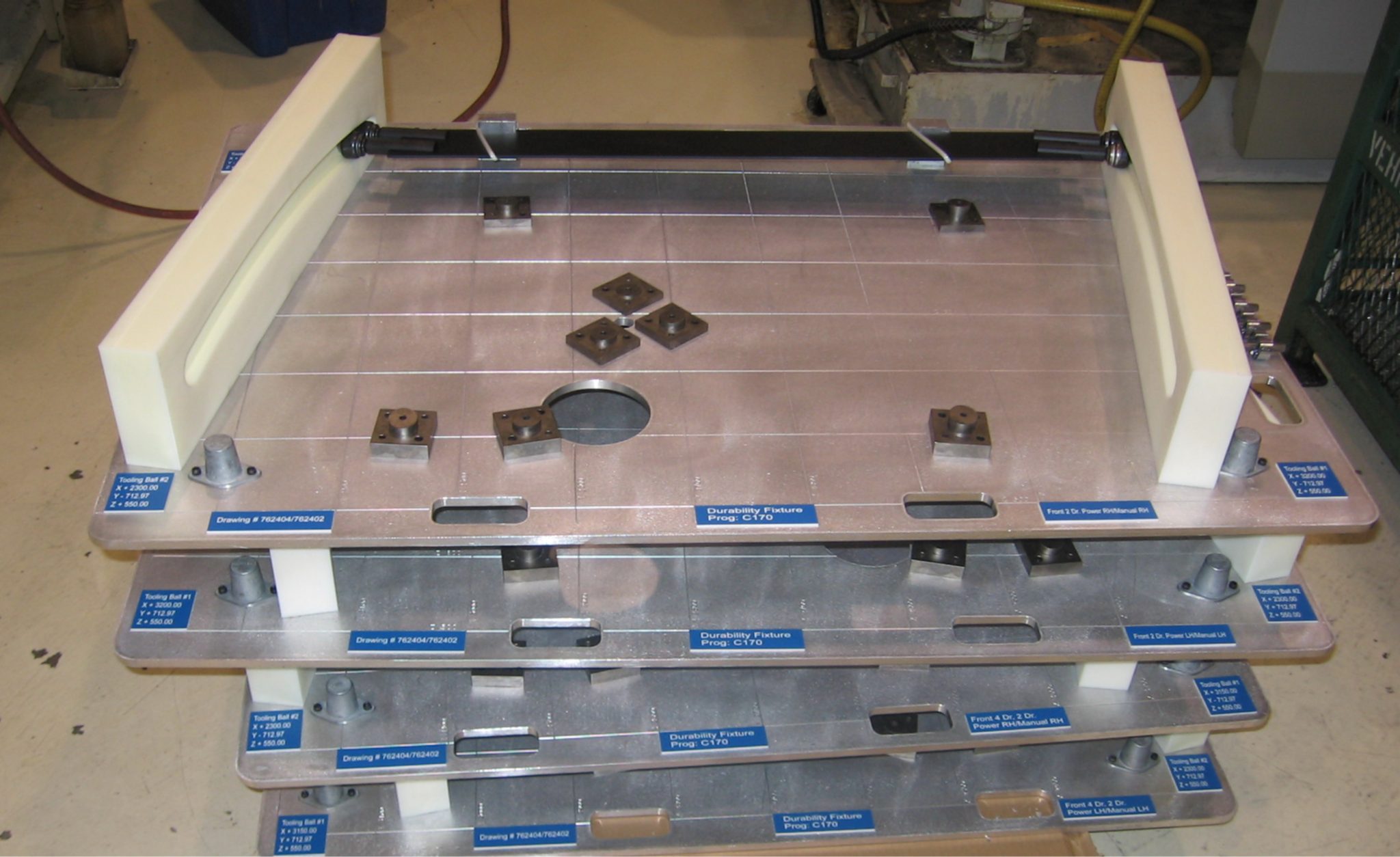

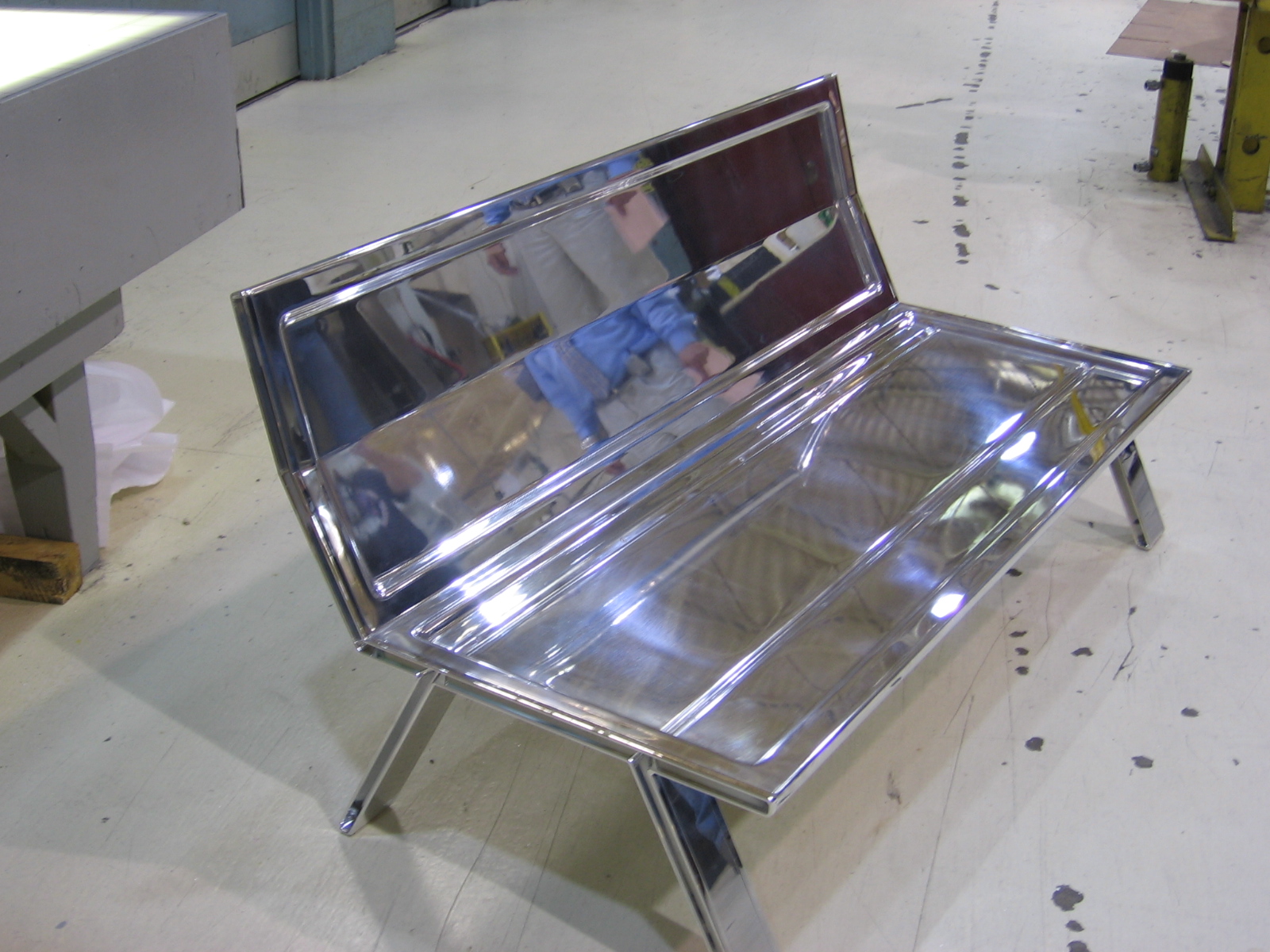

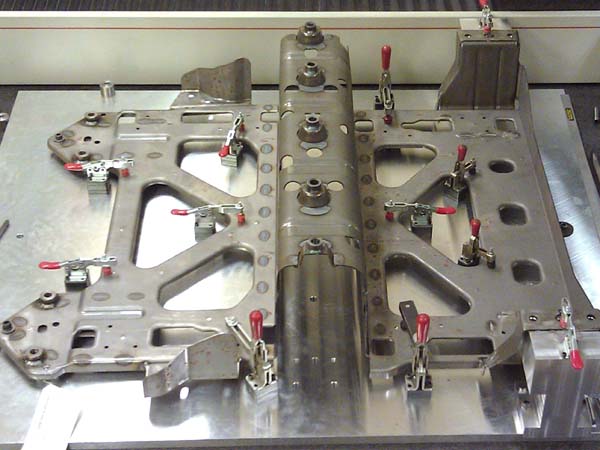

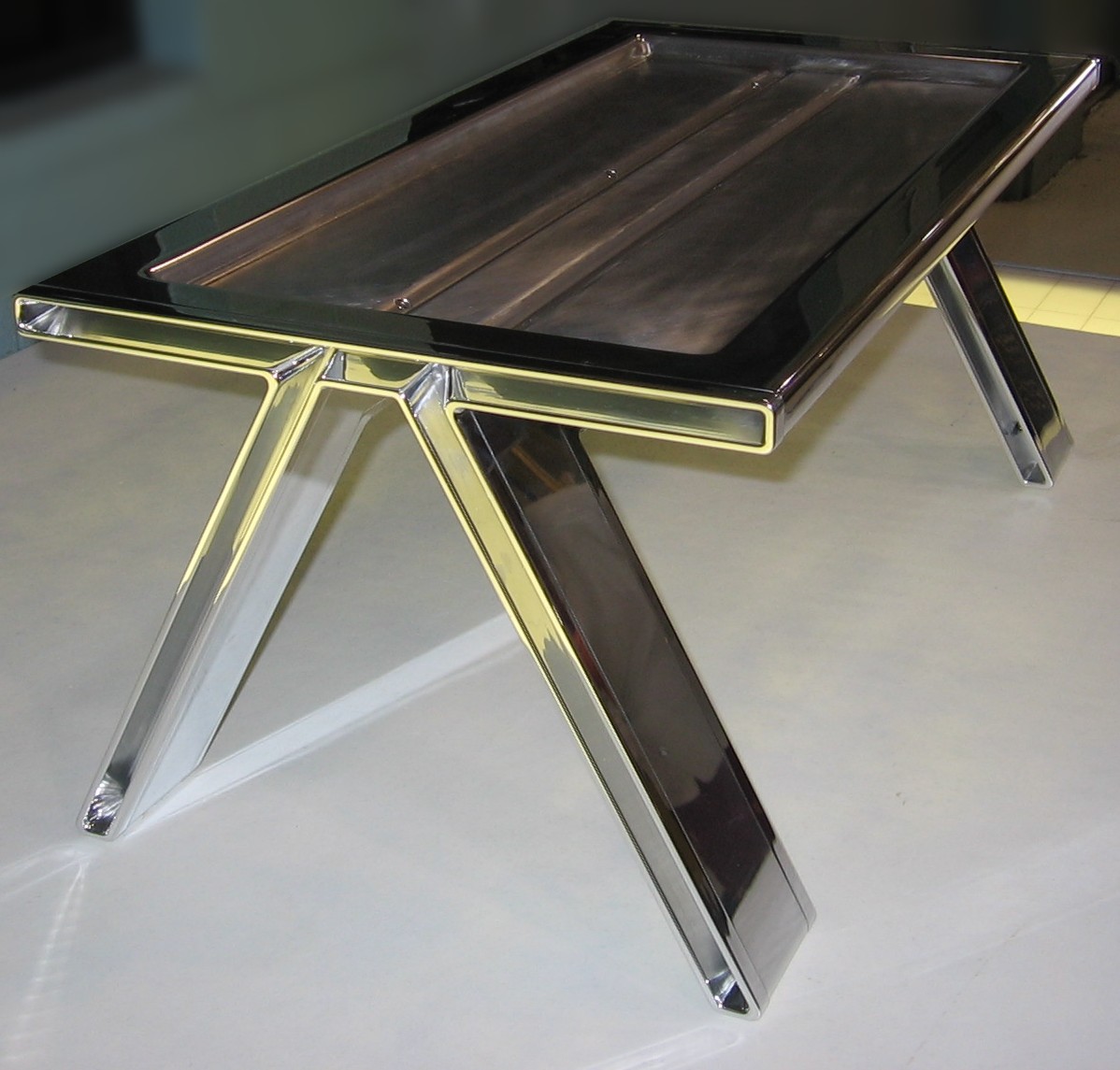

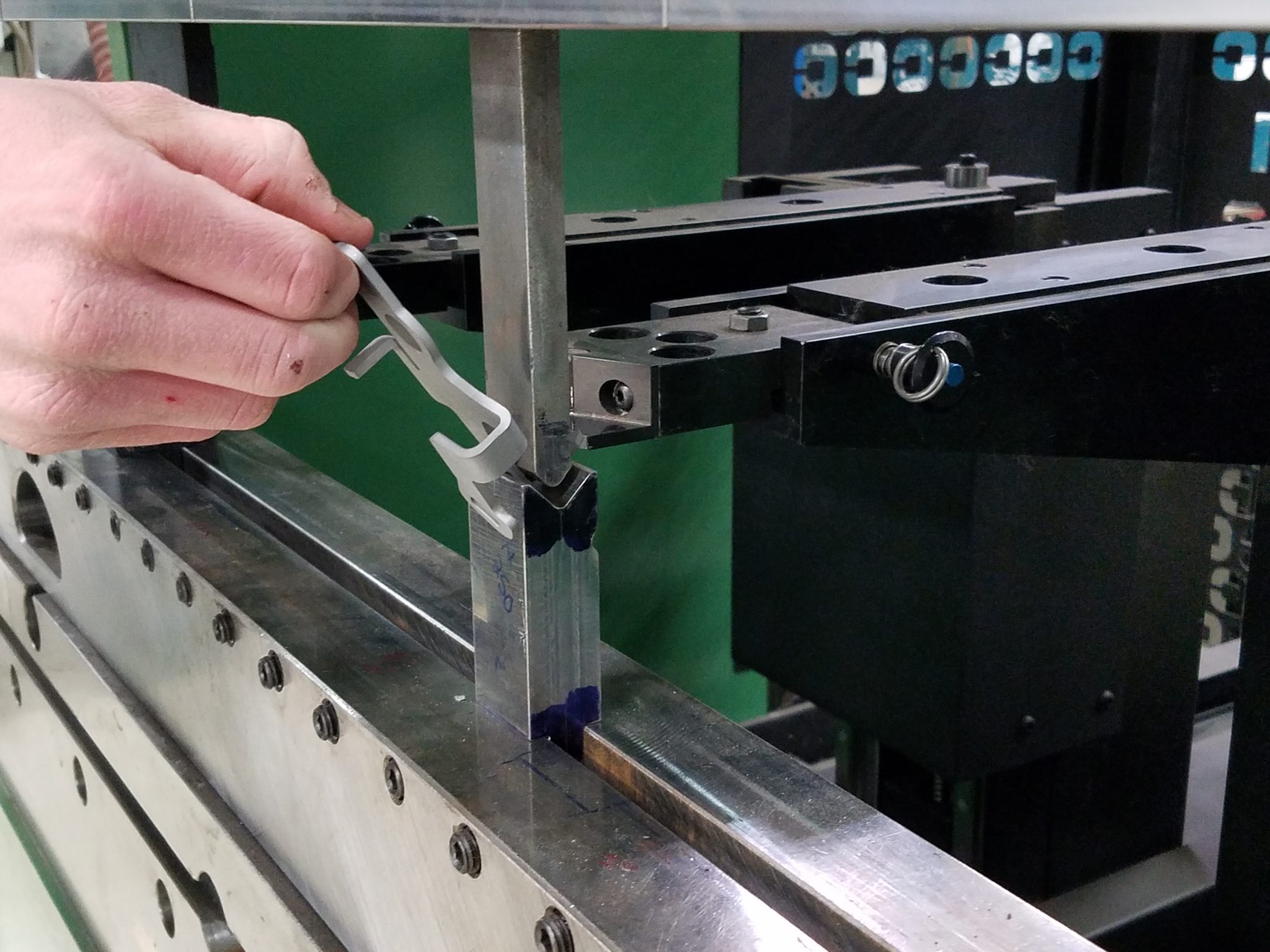

Metal Fabrication

- Fixtures and Fixture Design

- CNC controlled bending and forming

- 12′, 175 ton, and 6-axis back gauge press brakes

- Part marking utilizing lasers, dot peen, and controlled engraving

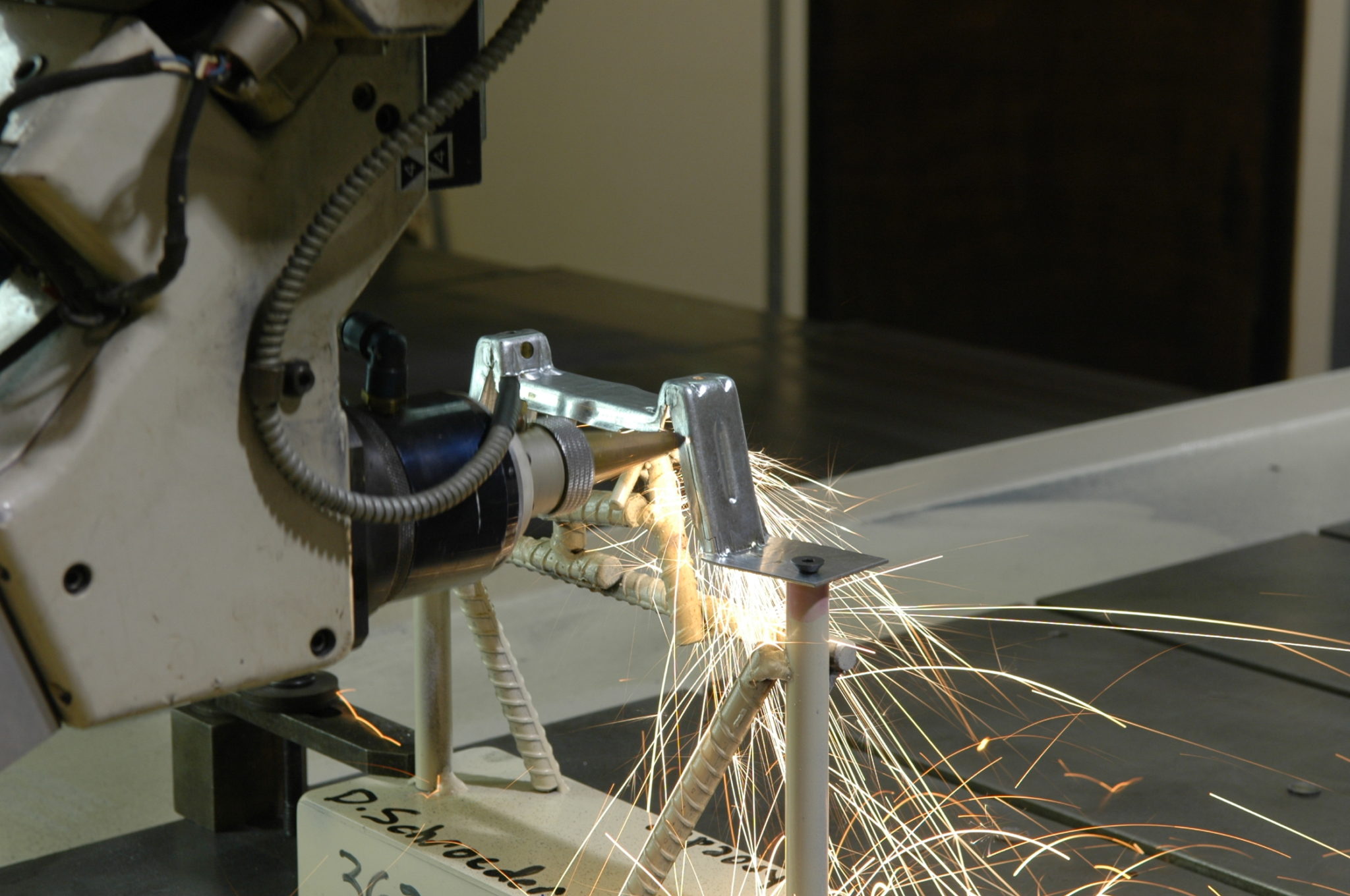

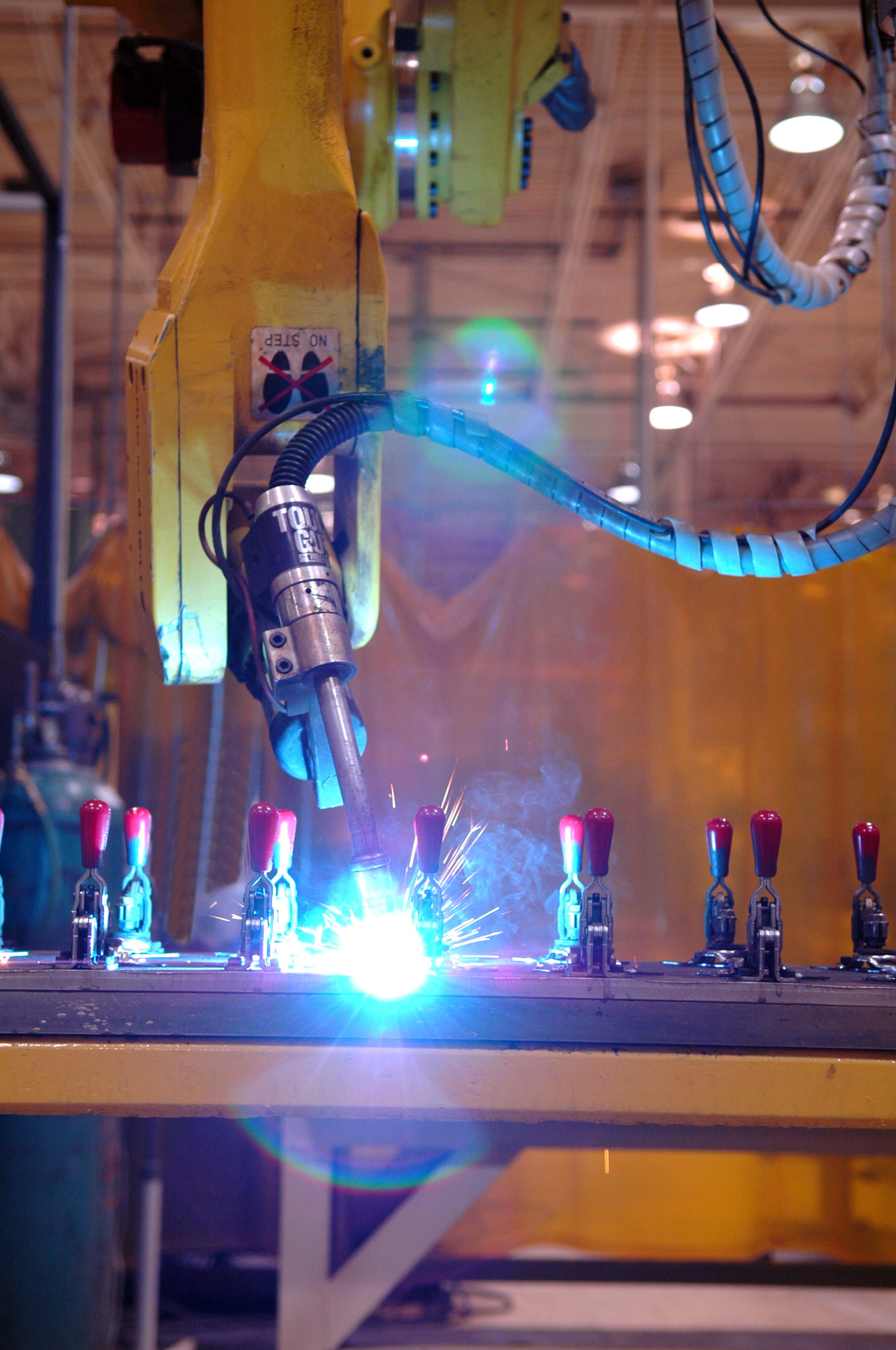

Robotic Welding

- Certified welding personnel

- 6-axis robotic welder with two horizontal rotaries

- Certified GMAW (MIG), GTAW (TIG), and RSW processes

- RSW up to 150kva

Short Run Production

We can provide short run/limited production services for a range of diverse projects utilizing our vast experience and equipment.

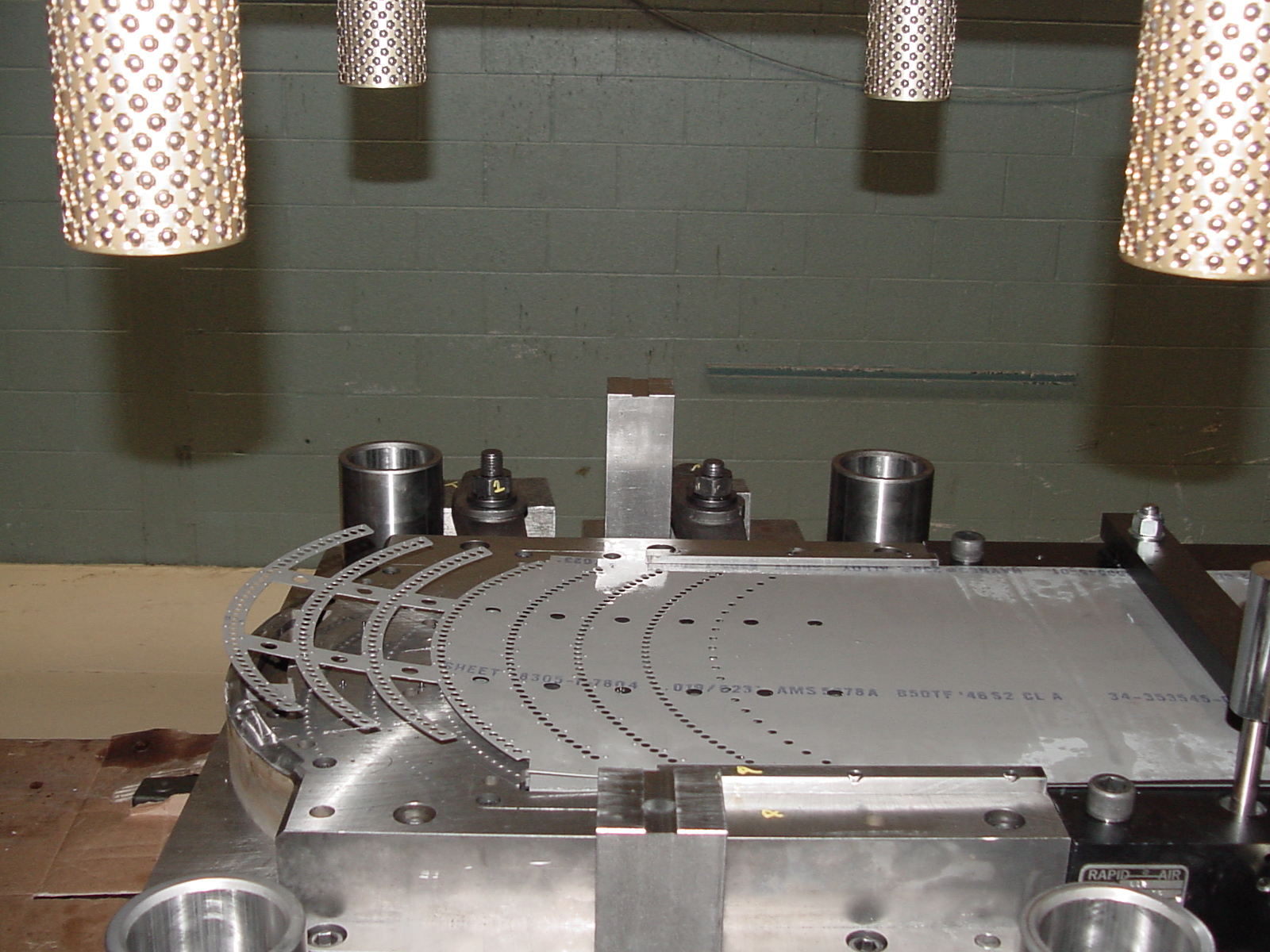

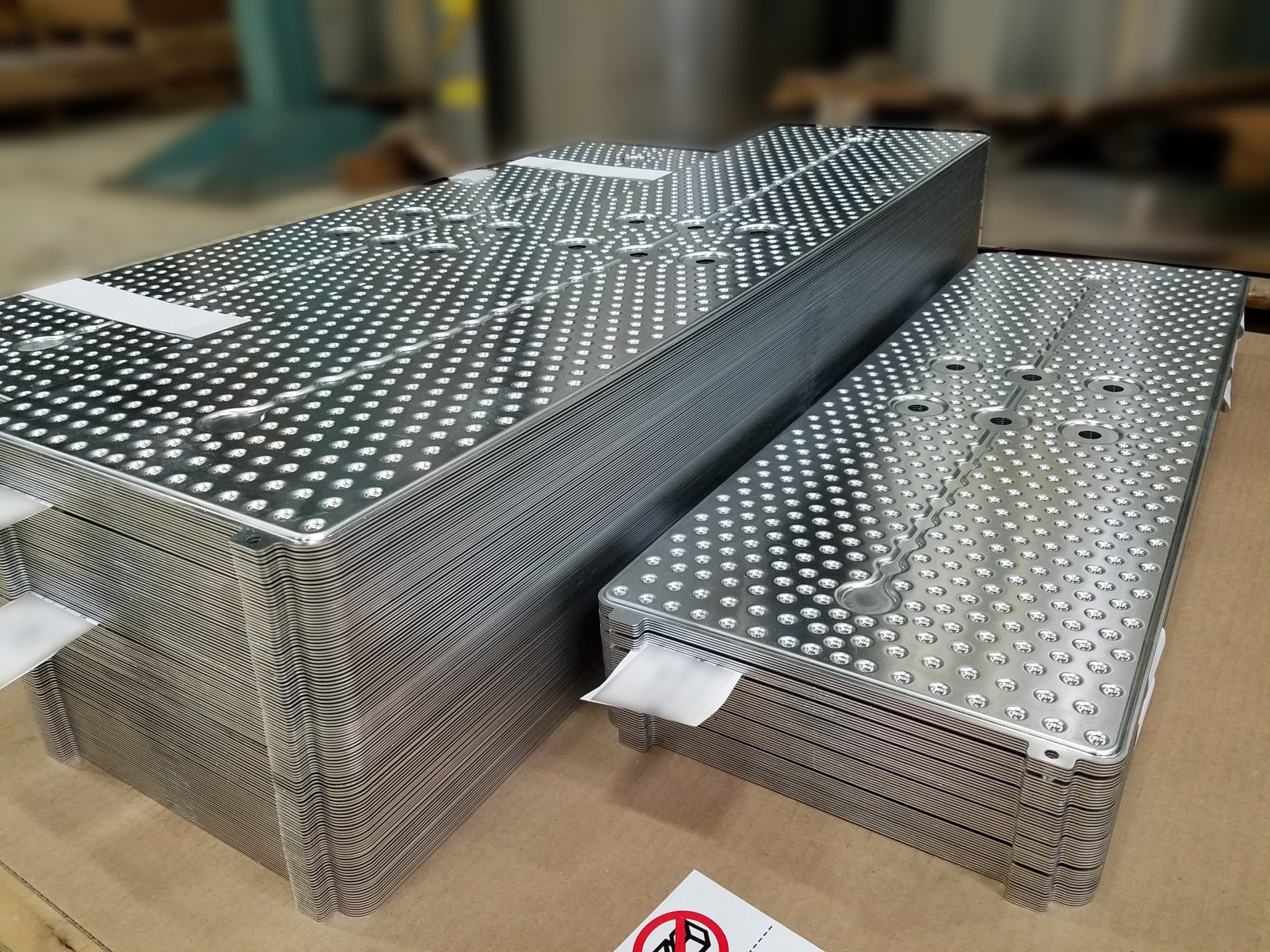

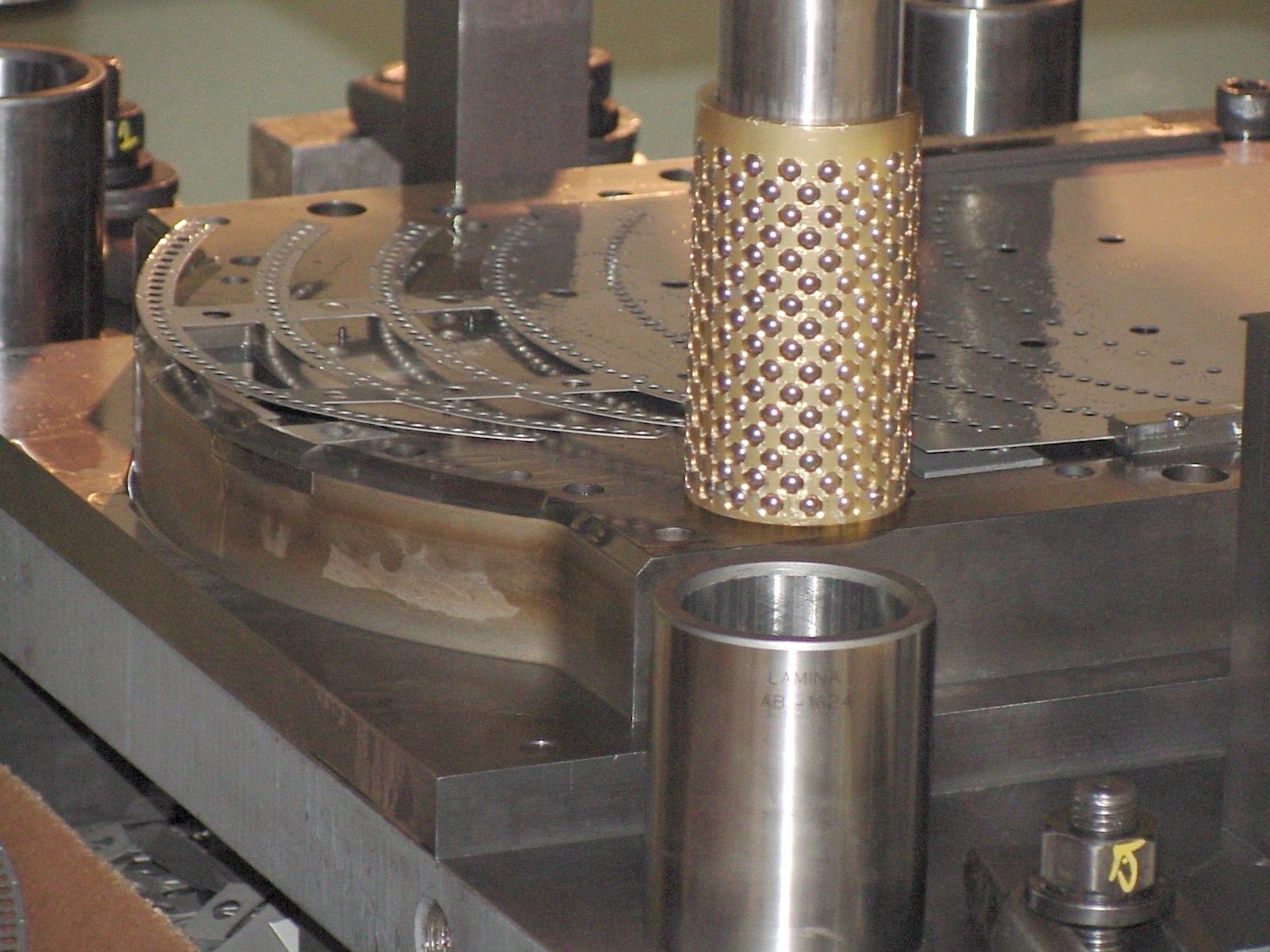

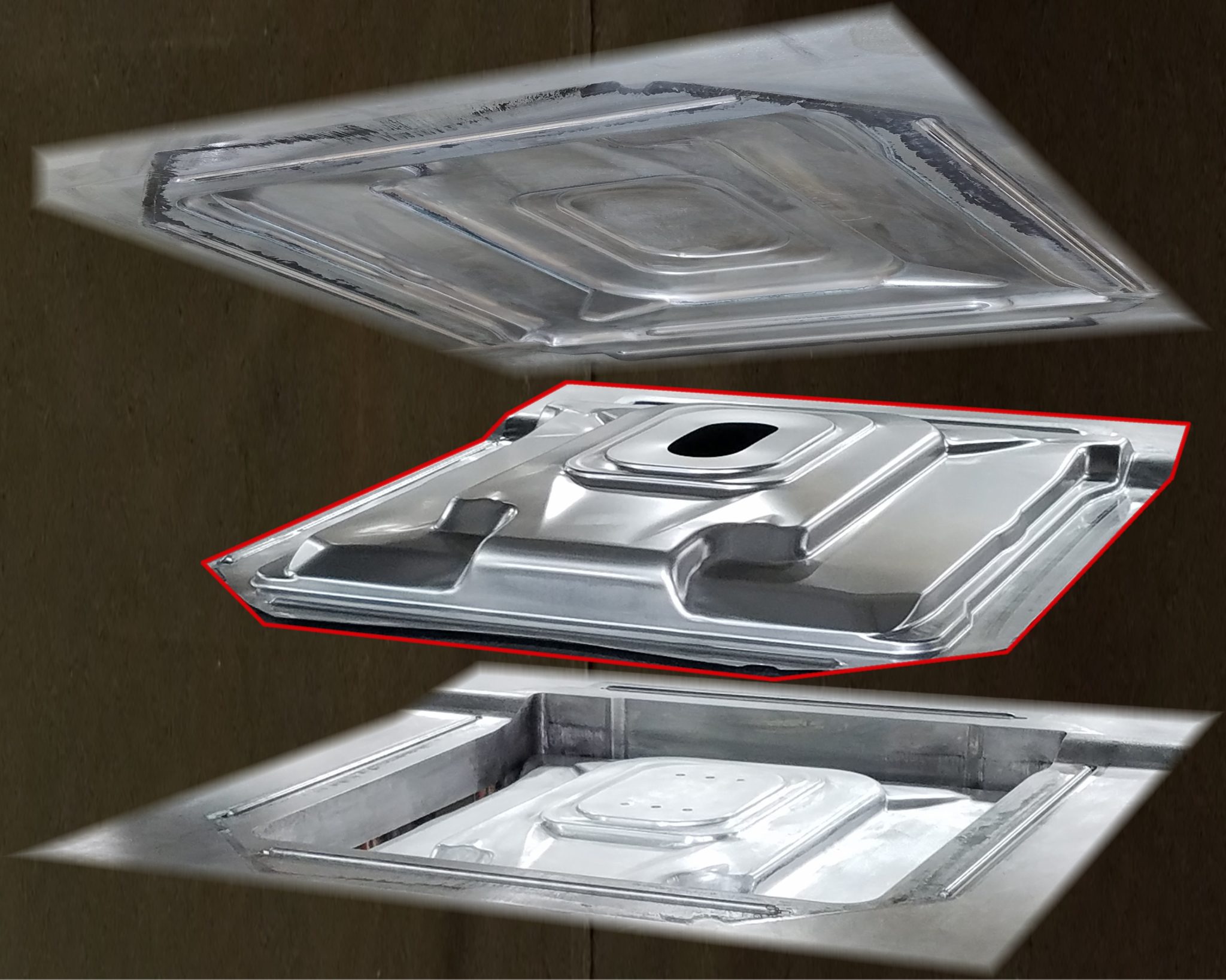

Stampings

- Deep draws up to 16″

- Forming force: 50 to 5,500 tons and up to 600 tons of binder force

- Bed sizes up to 15′ x 7′

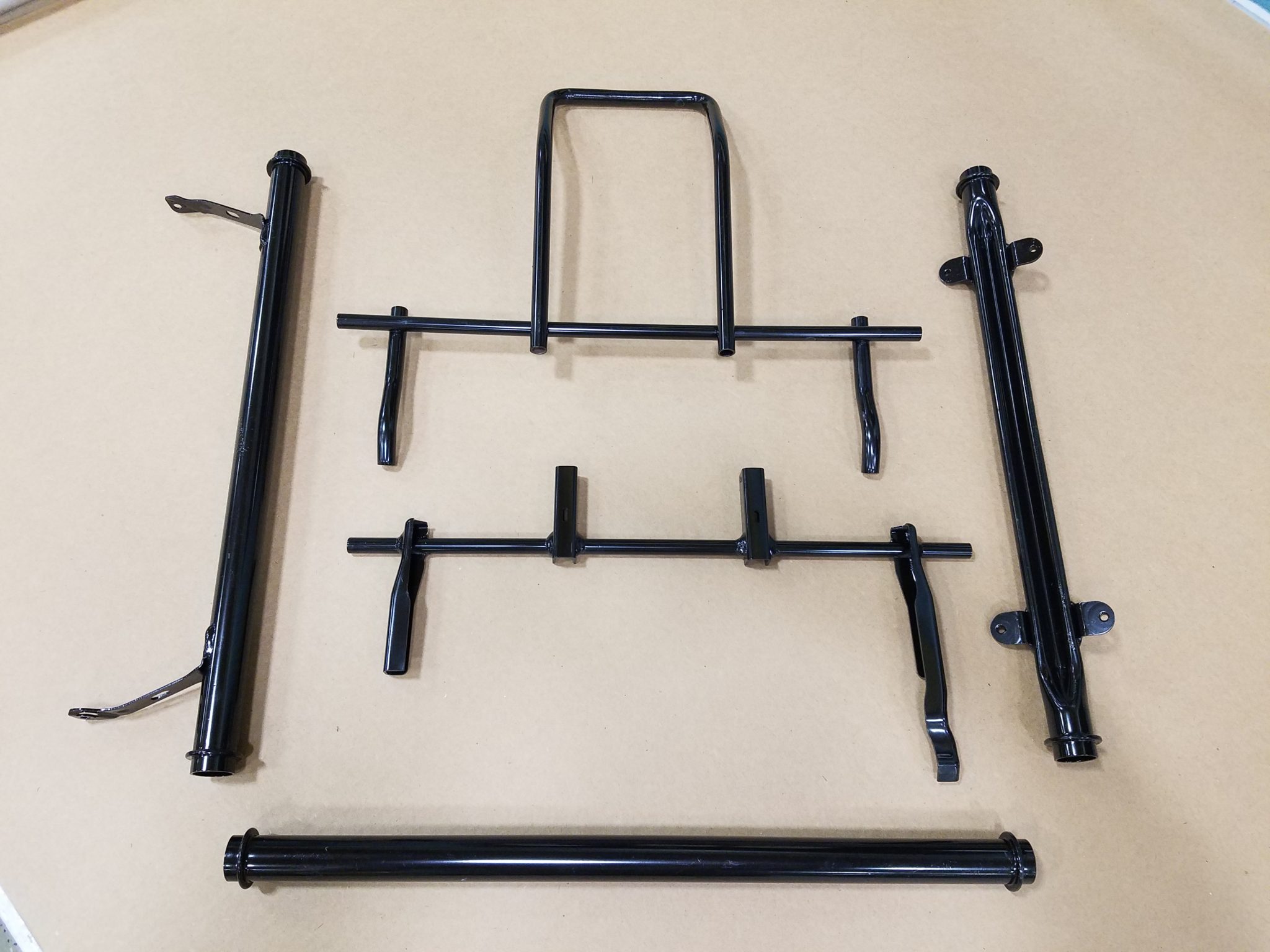

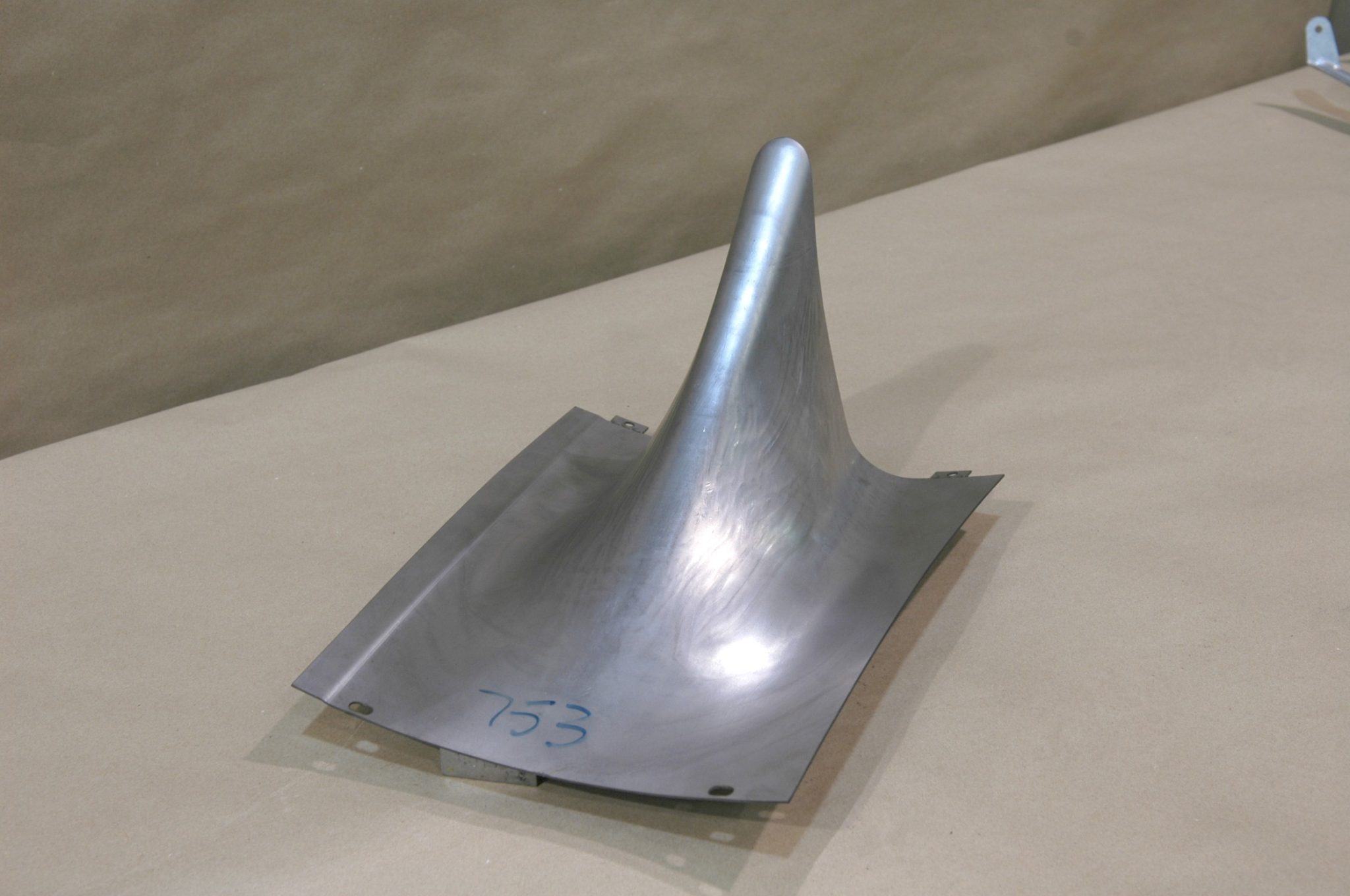

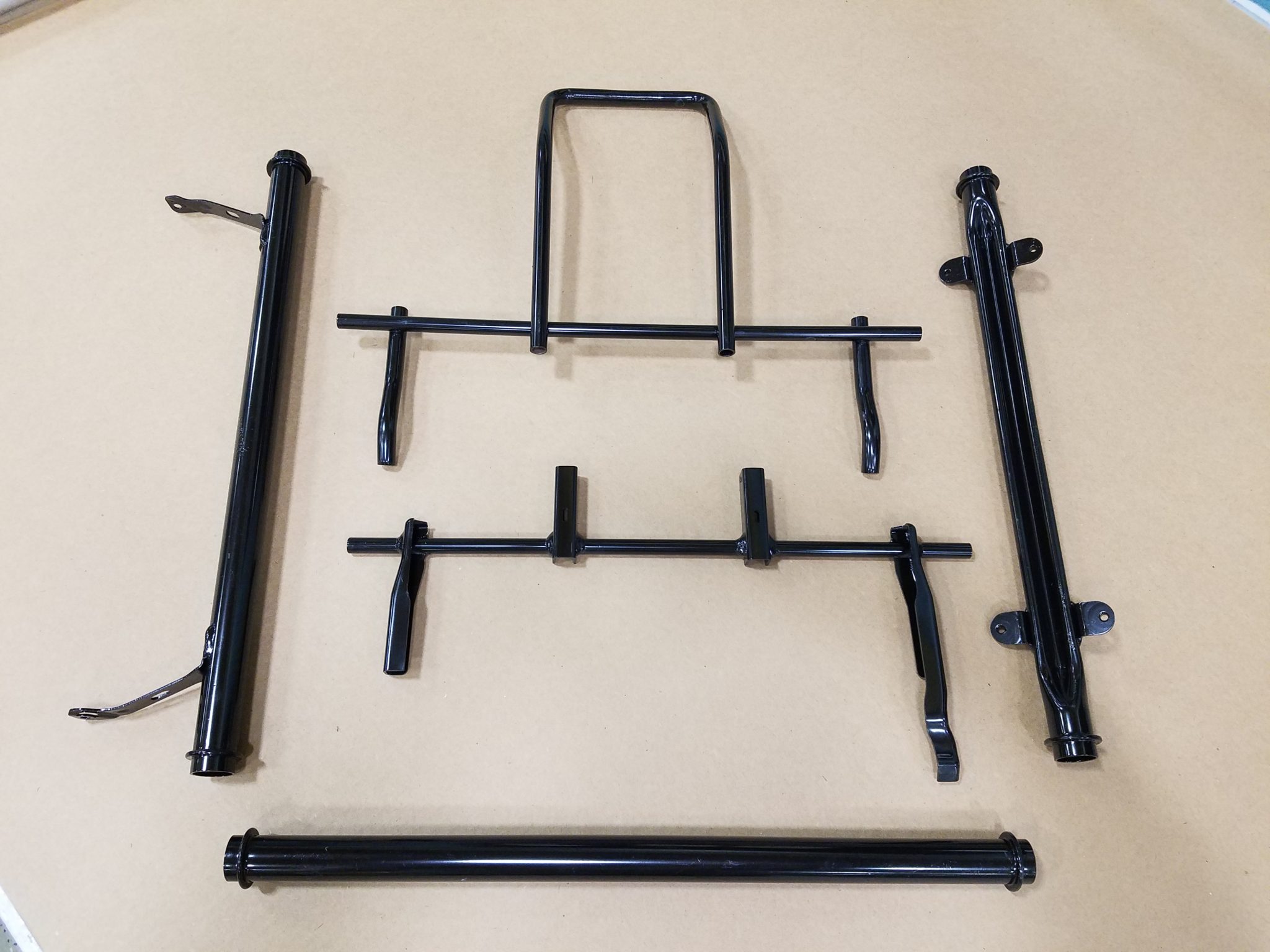

Tube Forming

- NC controlled tubular bending

- Tubular end forming

- Tubular bead forming

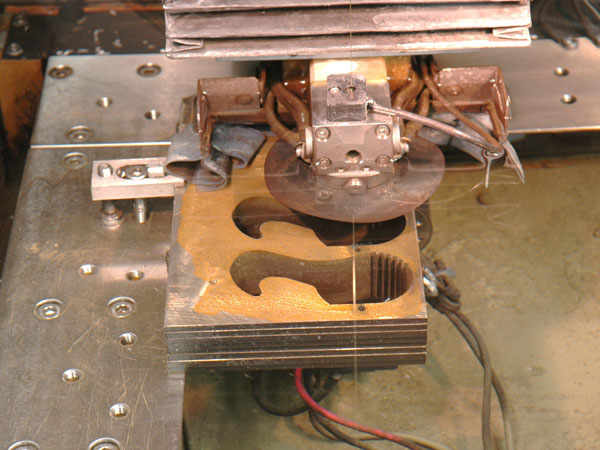

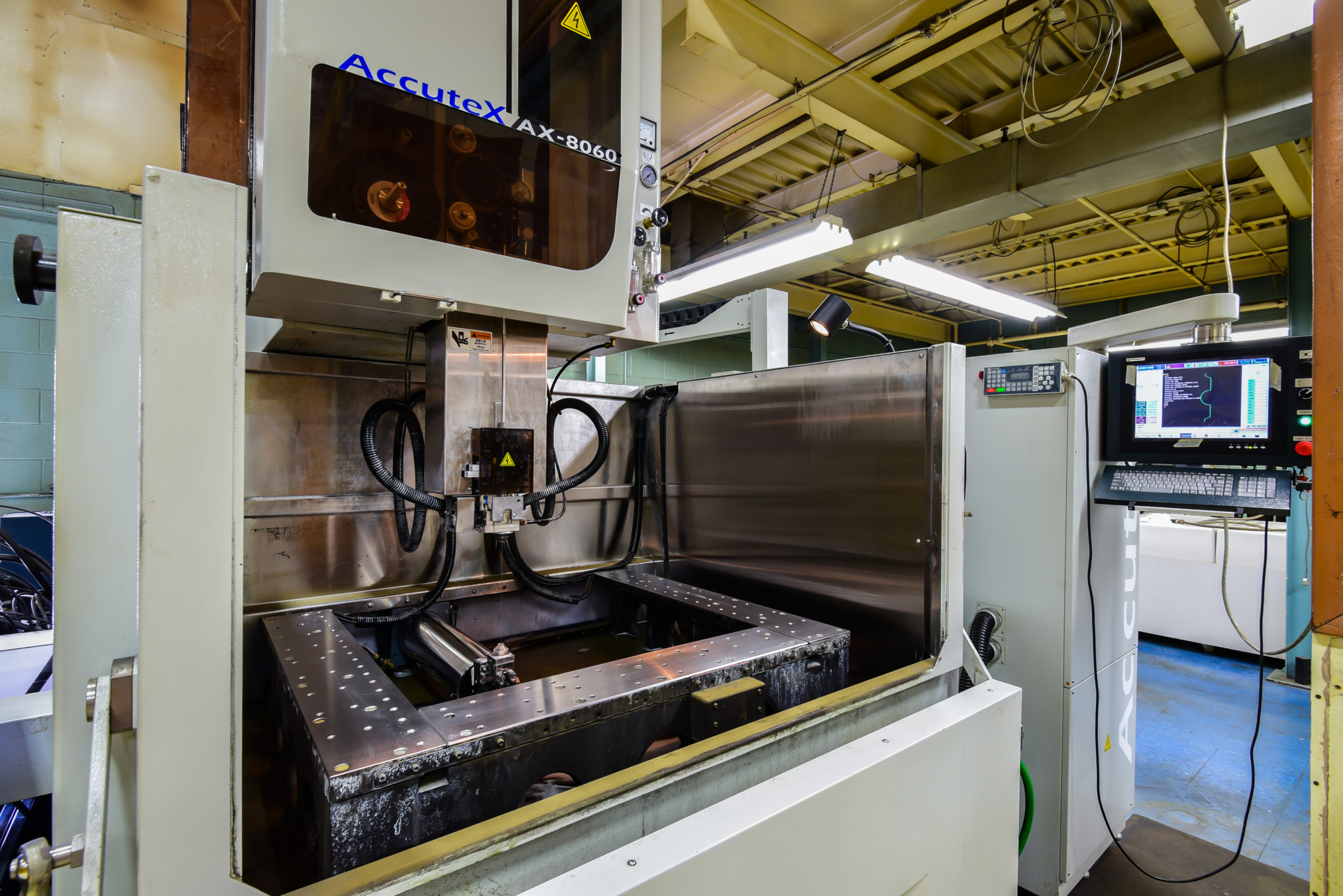

Wire EDM

- Precision parts with extremely tight tolerances

- 5 axis Wire EDM

- 24″ cutting capacity

- 52″ x 39″ Envelope