Metal Fabrication

In today’s highly competitive manufacturing environment, a supplier able to promptly, professionally and reliably address all facets of your project can be your most valuable asset. You can always count on the Quasar team to cover every aspect of your job, from the fixture to the finished part! We maintain a full complement of lathes, drill presses, grinders and many other miscellaneous tools necessary for the quality performance of complete metal processing.

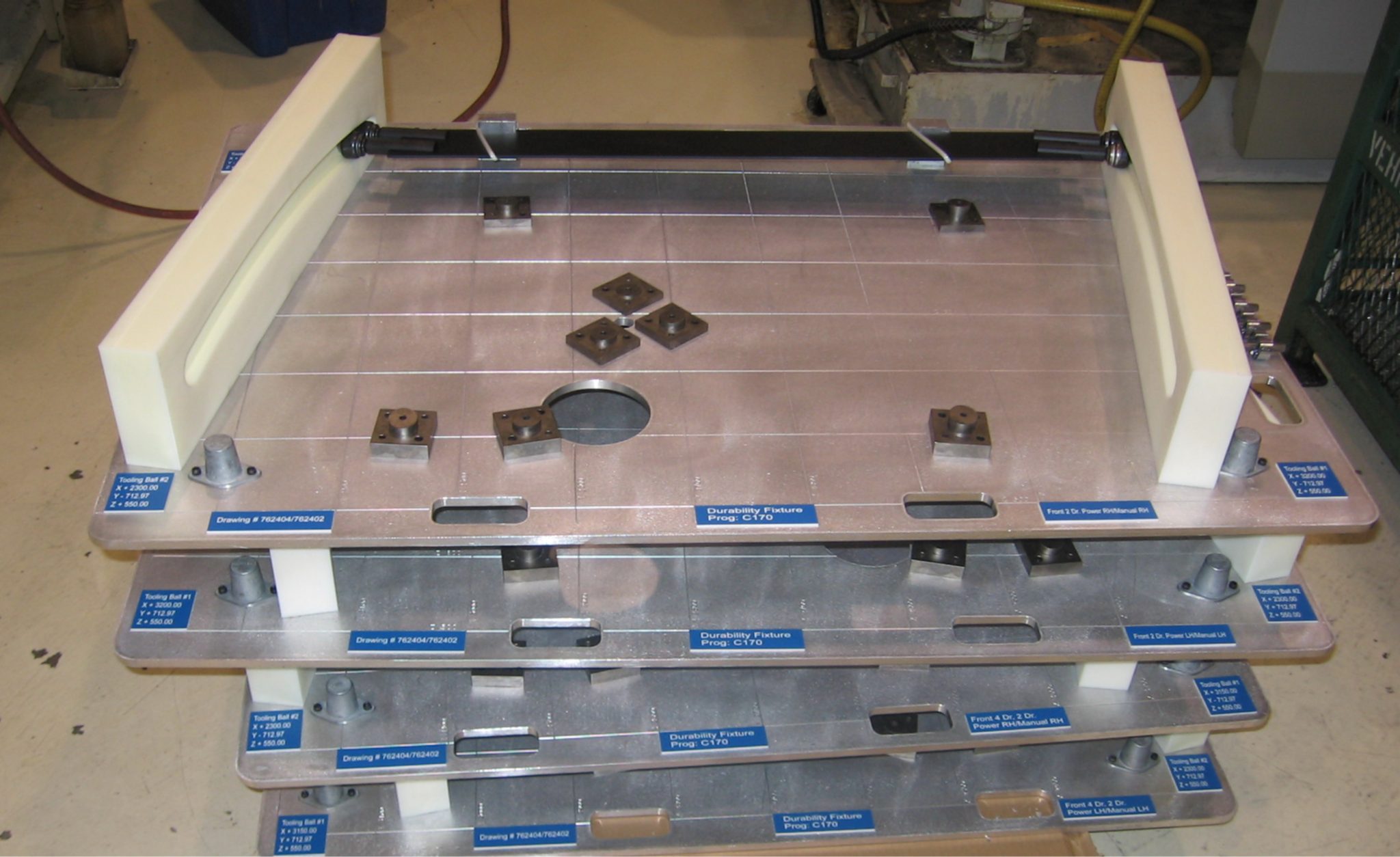

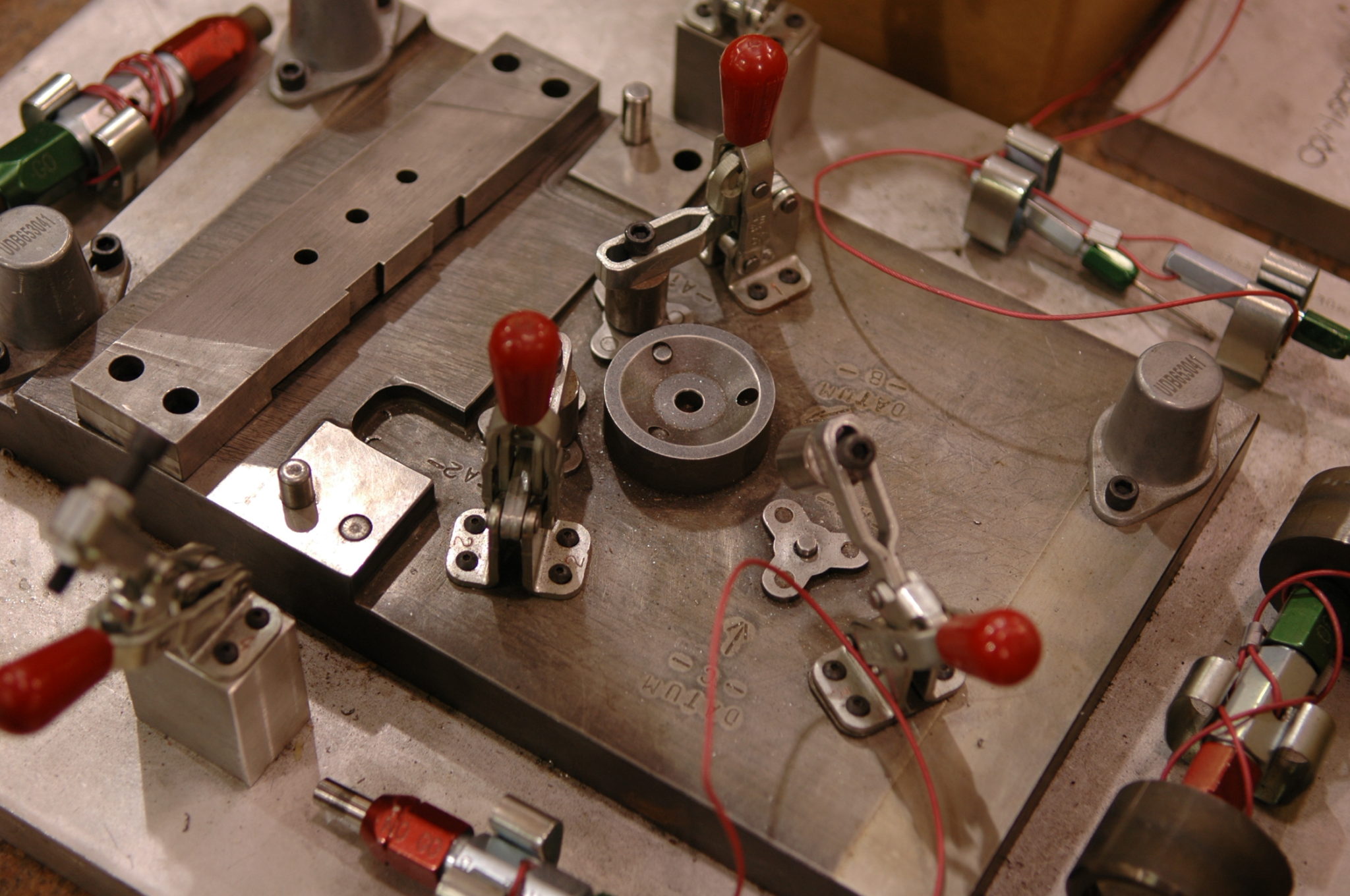

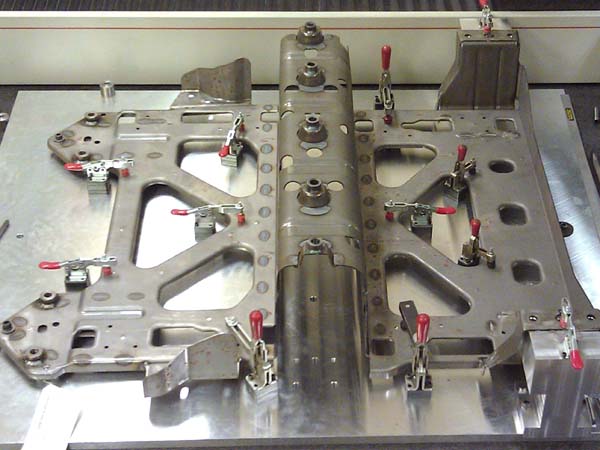

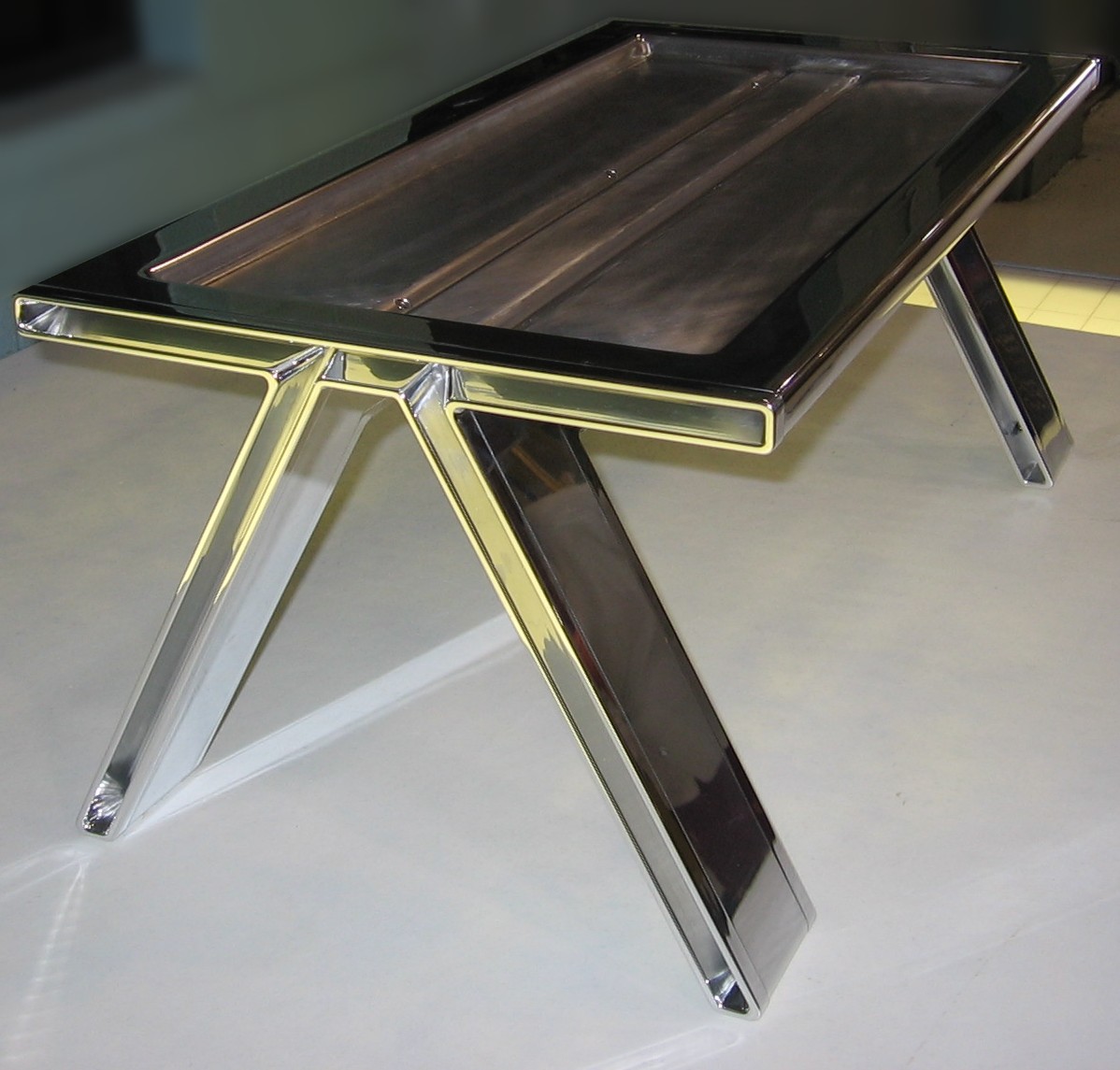

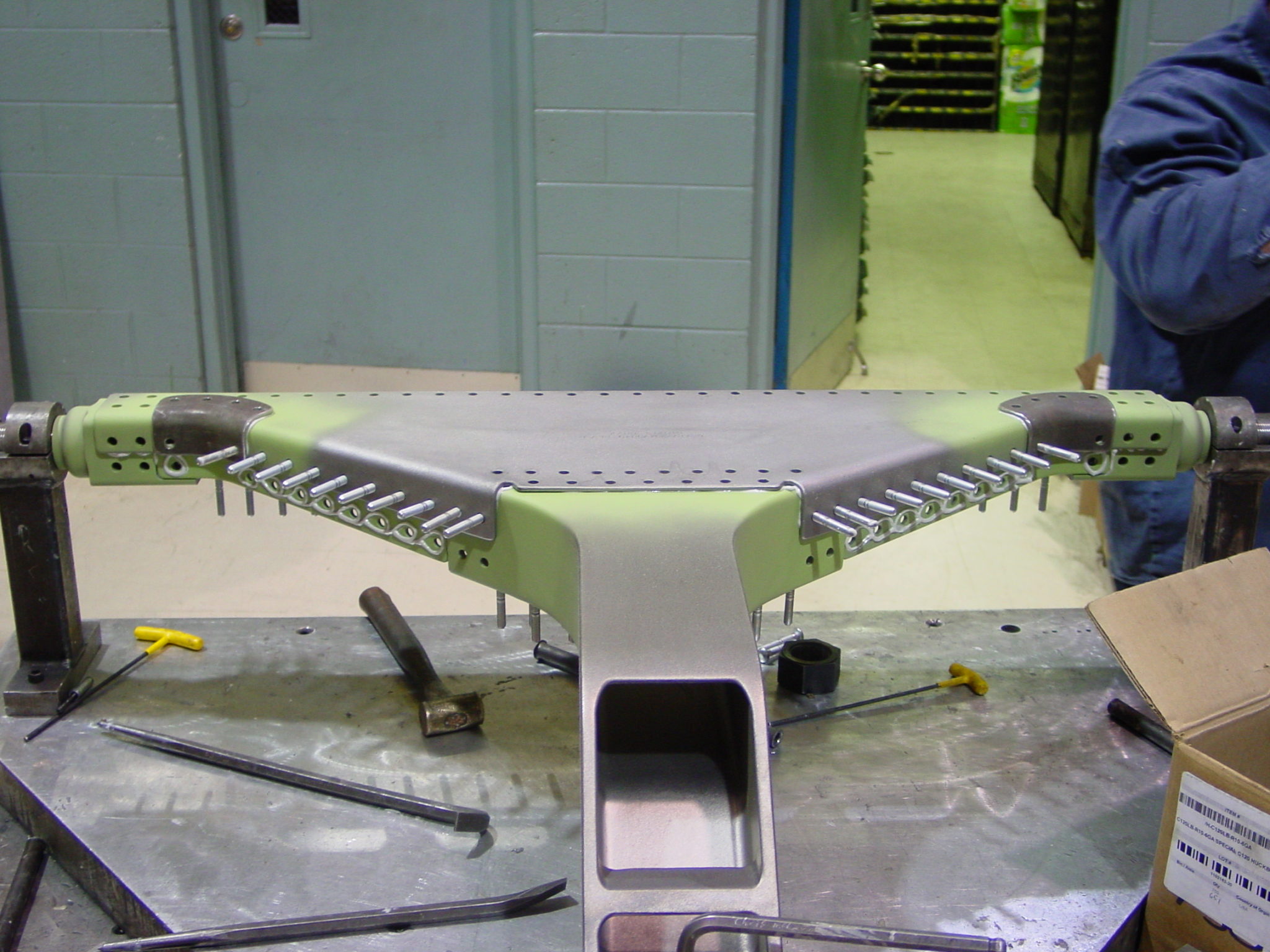

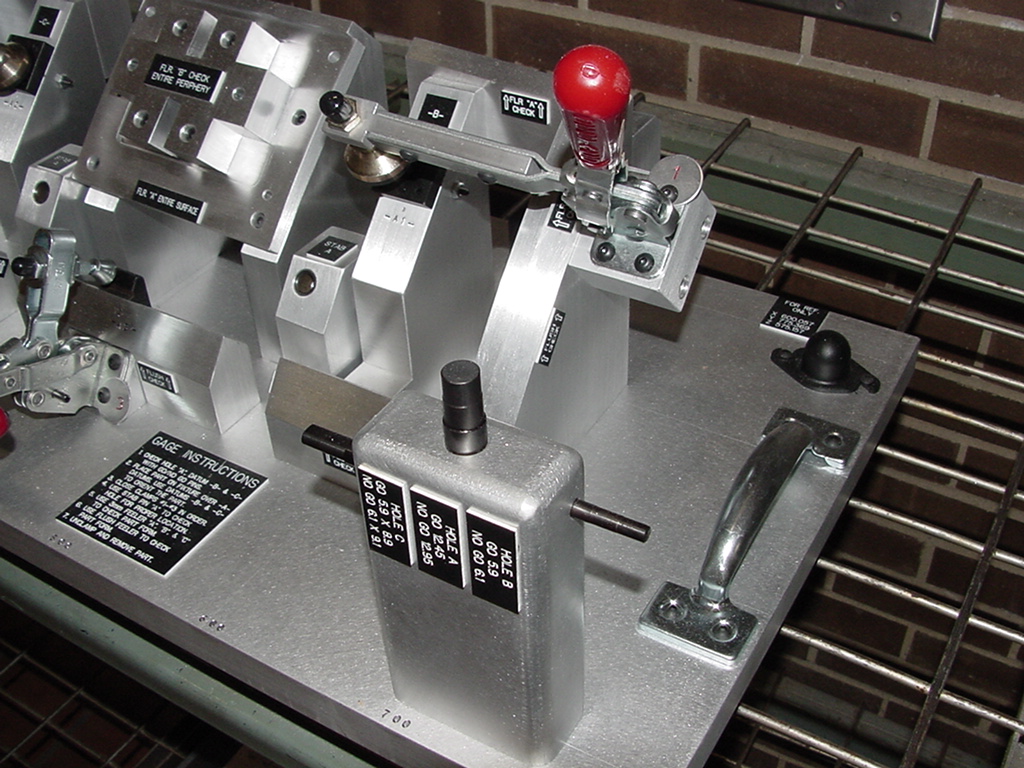

Fixtures and Fixture Design

Our in-house design department can quickly and accurately work out the details of any fixture concept. Once the design phase is finalized, our expert craftsmen take over by utilizing an extensive combination of tools and processes to create a fixture suitable for prototypes or short-run production.

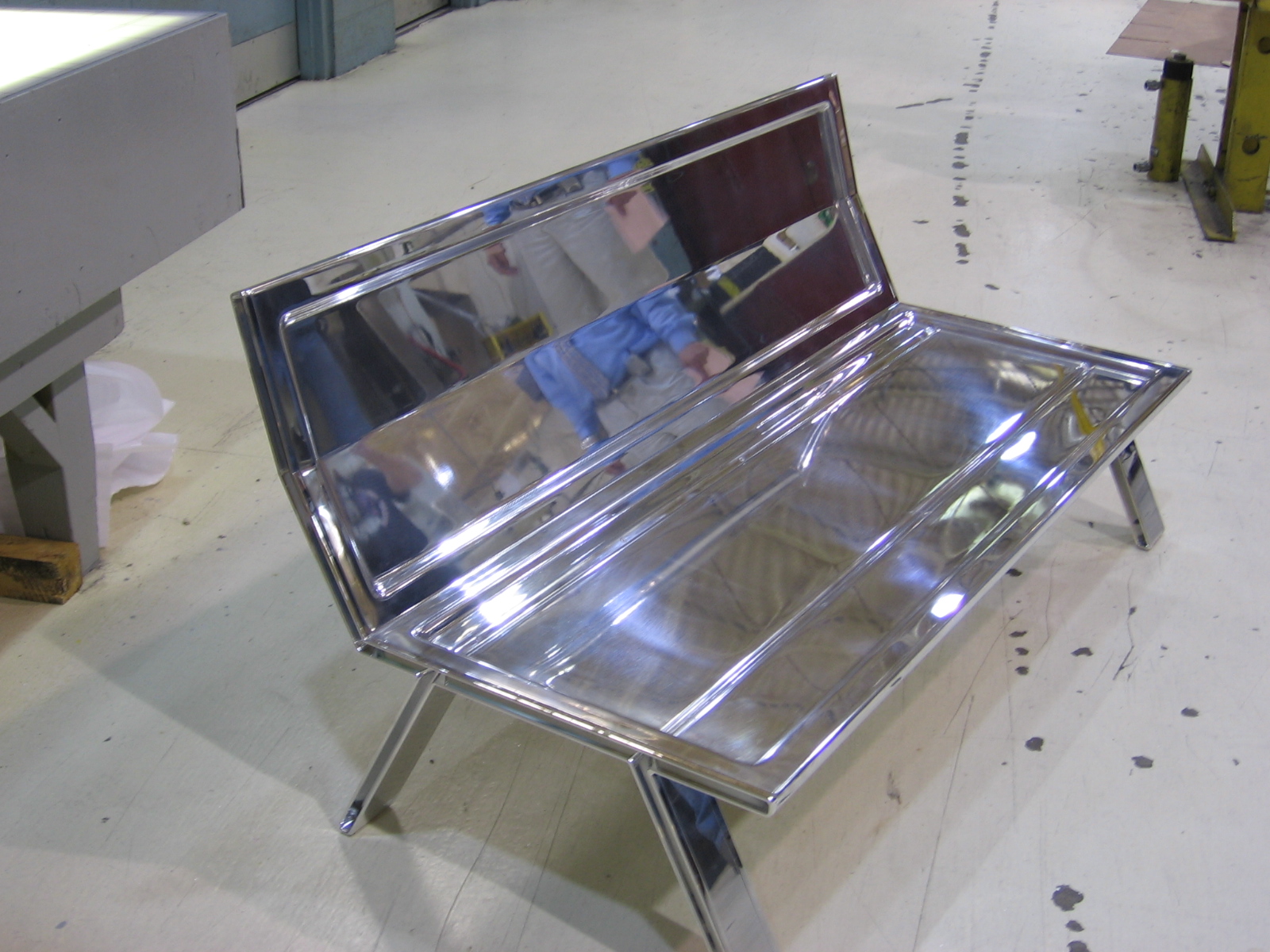

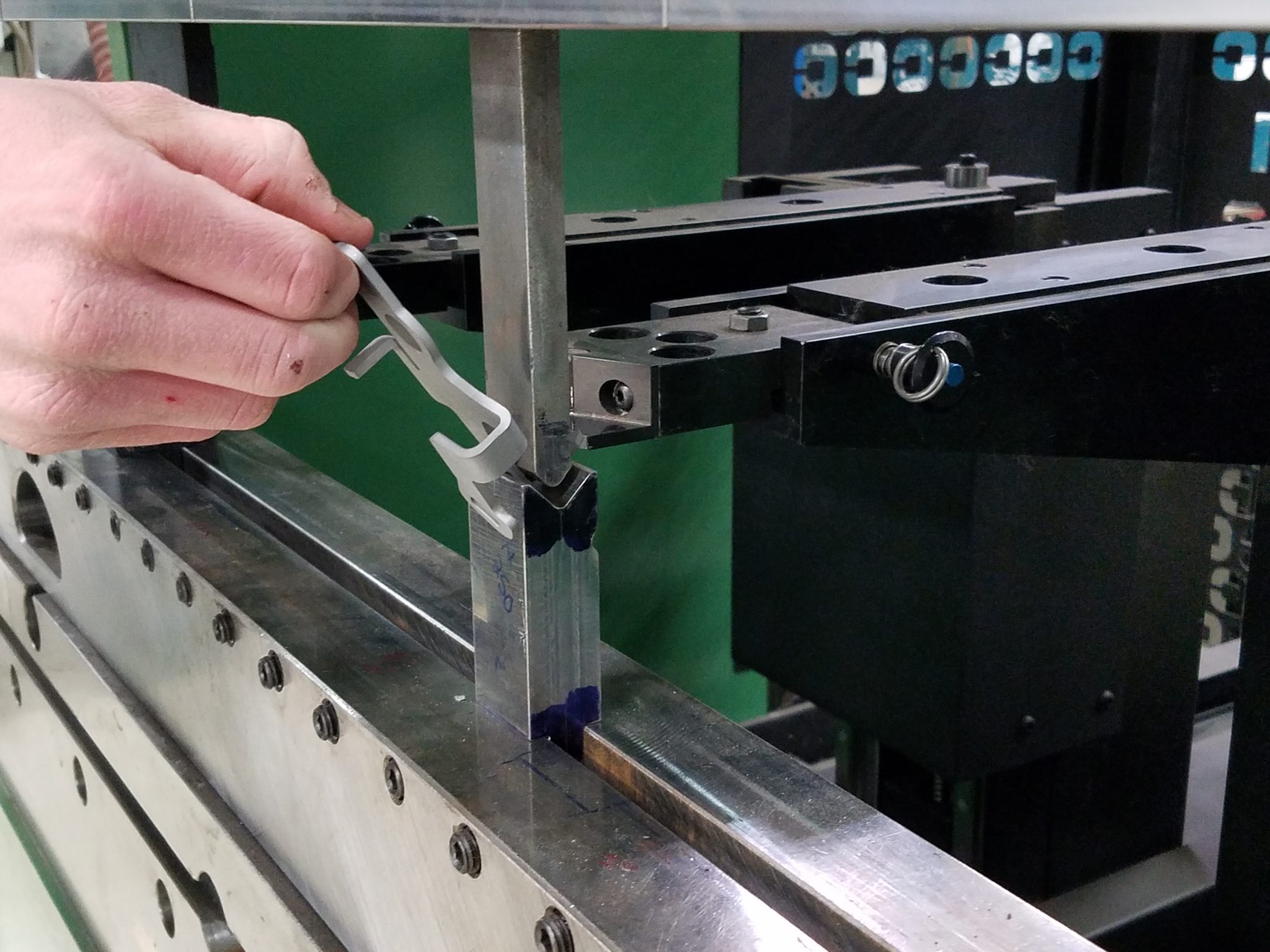

Bending and Forming

We have 15 hydraulic press brakes and 23 pneumatic press brakes. From small intricate precision components to large high strength parts, Quasar will proficiently meet all your bending and fabricating needs.

- 2 Cincinnati CNC Hydraulic Press Brakes with Programmable 6 axis Back-Gage

- Up to 12′ in length and 240 tons

Part Marking

In order to more efficiently comply with industry standards and customer requirements, we have enhanced our ability to mark our manufactured or customer supplied components. Whether it be traditional metal stamps, ink stamp, chemical etching, dot-peen, mechanical engraving or laser etching, we are ready to meet your job-specific demands.

- Traditional Metal Stamps

- Manual or controlled engraving

- CNC Dot-Peen engraving

- CO2 Laser Engraving

- Fiber Laser Engraving