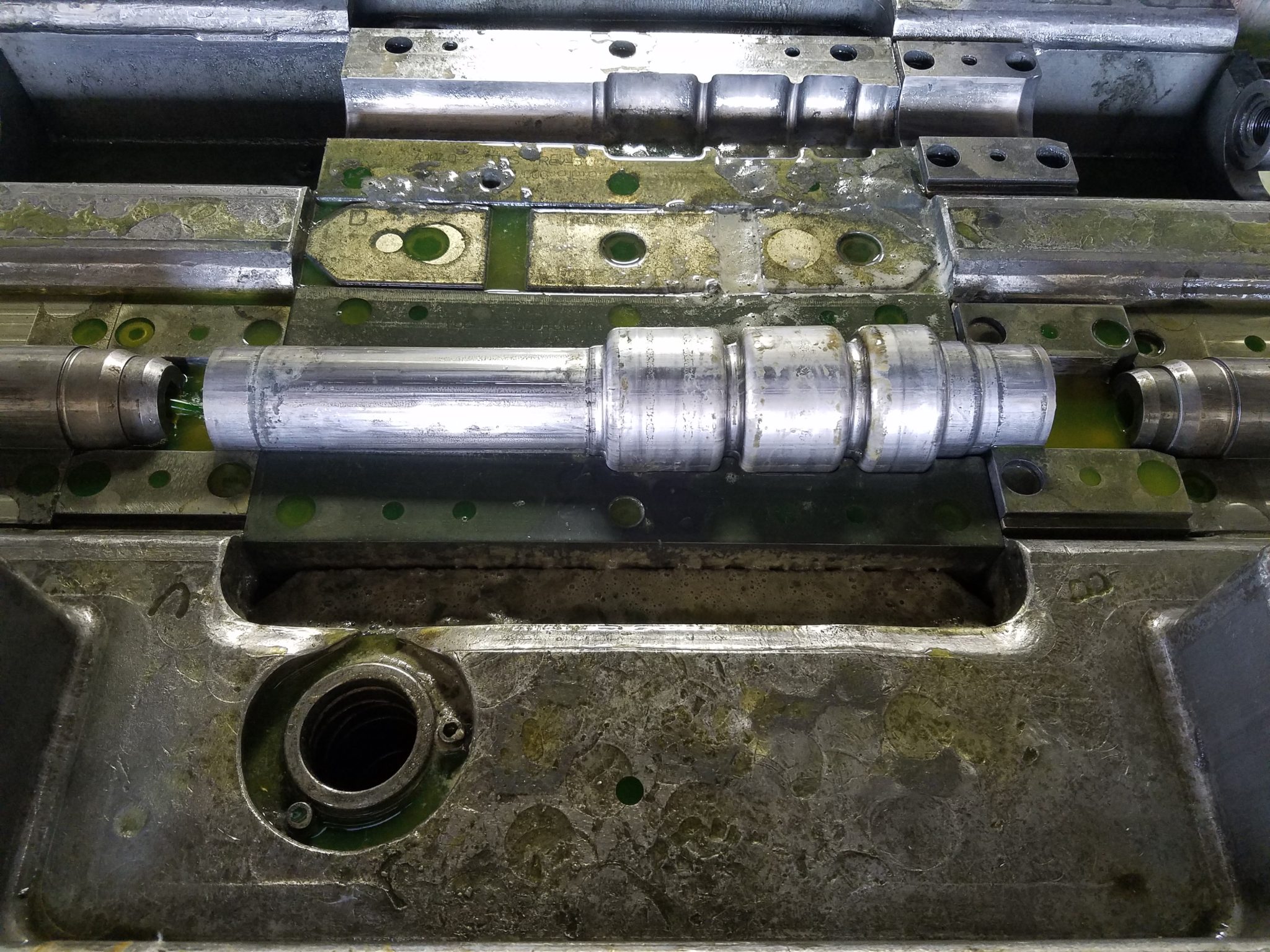

Hydroforming

With our 4000 bar (58,000 psi) water hydraulic pressure and 178” x 85” bed size, Quasar is prepared to successfully meet all of the challenges presented by your hydroform project requirements. In 2016, we substantially updated our Schuler Hydroform Press with the installation of new Allen Bradley logic with safety integrated controls and new Schuler HMI. These enhancements ensure our complete and accurate control over the hydroforming process through programming and monitoring the position, force, pressure, and velocity of each component of the hydroforming process.

Whether you have a project using existing tooling or a new project requiring new tooling, Quasar has the expertise and knowledge to manufacture all the tooling for tube bending, pre-form or precrush, and hydroforming processes. We also have the capacity to prove out our tooling design concepts with our PAMSTAMP tube bending/hydroforming simulation software. Couple this with our ability to produce customized tubing shapes and sizes to fit your design requirement and our inhouse tube bending capability, we can efficiently and accurately take your hydroform project from start to finish.

Hydroform Press Capabilities

- 178″ x 85″ bed size with 110,000 lb. capacity

- 75″ daylight opening and 35″ slide stroke

- 5,500 ton clamping force

- 58,000 psi (4,000 bar) internal forming pressure

- Rapid flood fill

- Hydro-Piercing

- Hydraulics can be controlled using position, force, pressure, and velocity

- Multiple auxilliary hydraulic ports for additional hydraulic functions